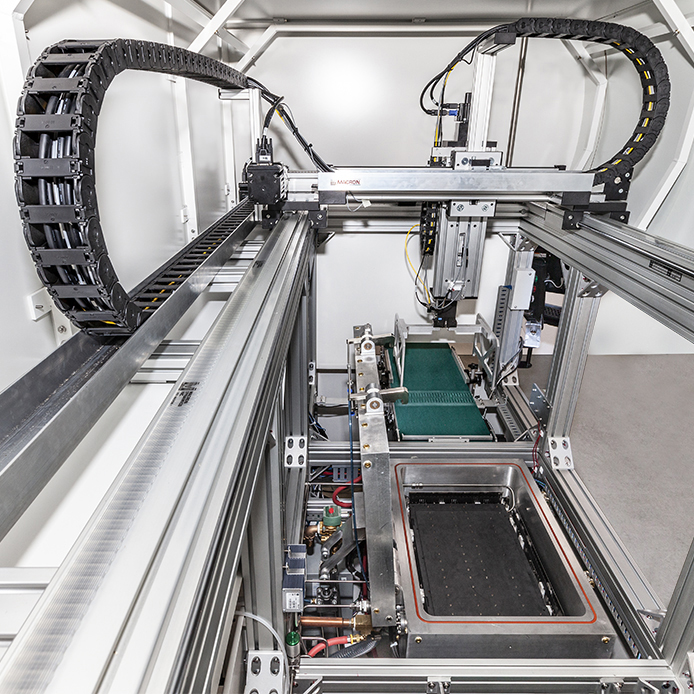

8300 Series Automated Vacuum Pressure Soldering System

8300 Series Automated Vacuum Pressure Soldering System

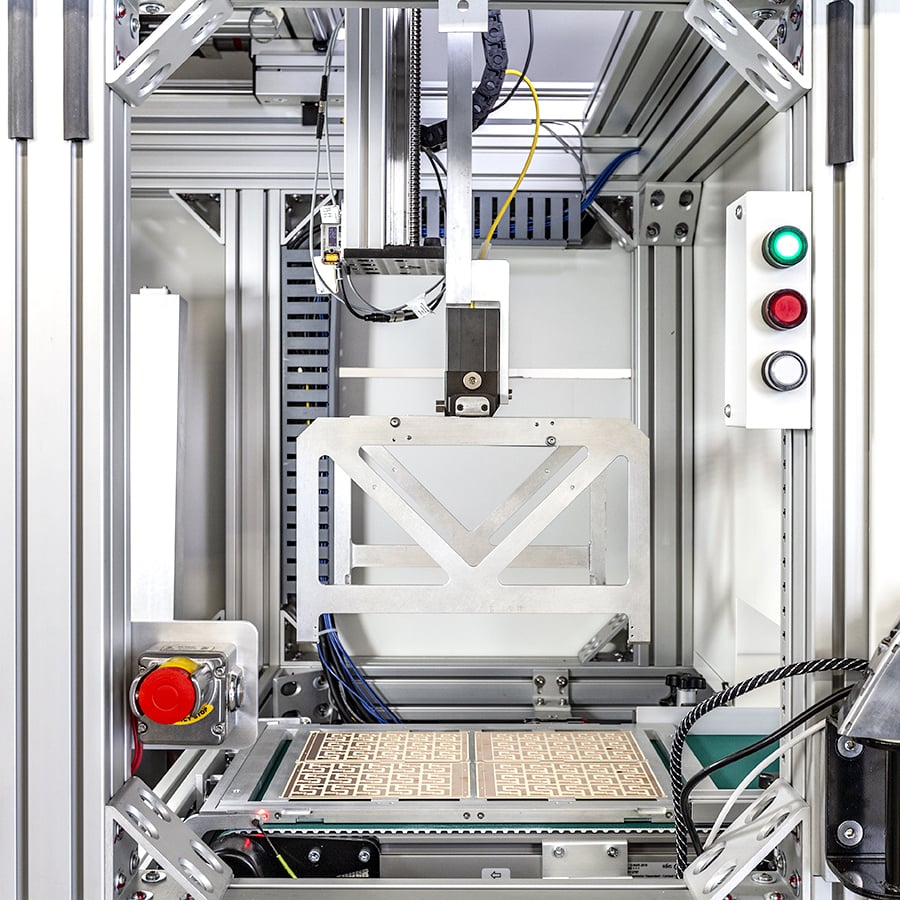

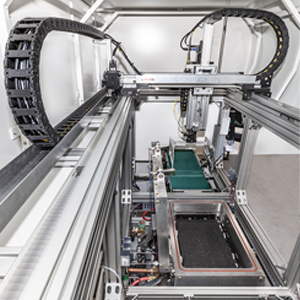

The SST 8300 Series is an automated vacuum pressure soldering system setting new industry standards for flux-less soldering by providing highly reliable and reproducible solder interfaces using precise combination of vacuum and gas pressure. Featuring conveyor belts and a Cartesian gantry, the system provides high volume, high reliable packages through precise control of the soldering process. Available with a single or triple chamber, the system allows for heating up to 500°C and fast cooling in an inert gas environment from vacuum levels below 50 millitorr to pressures up to 40 psig using the QuikCool™ cooling unit.

- IGBT Modules

- Power Module Assembly

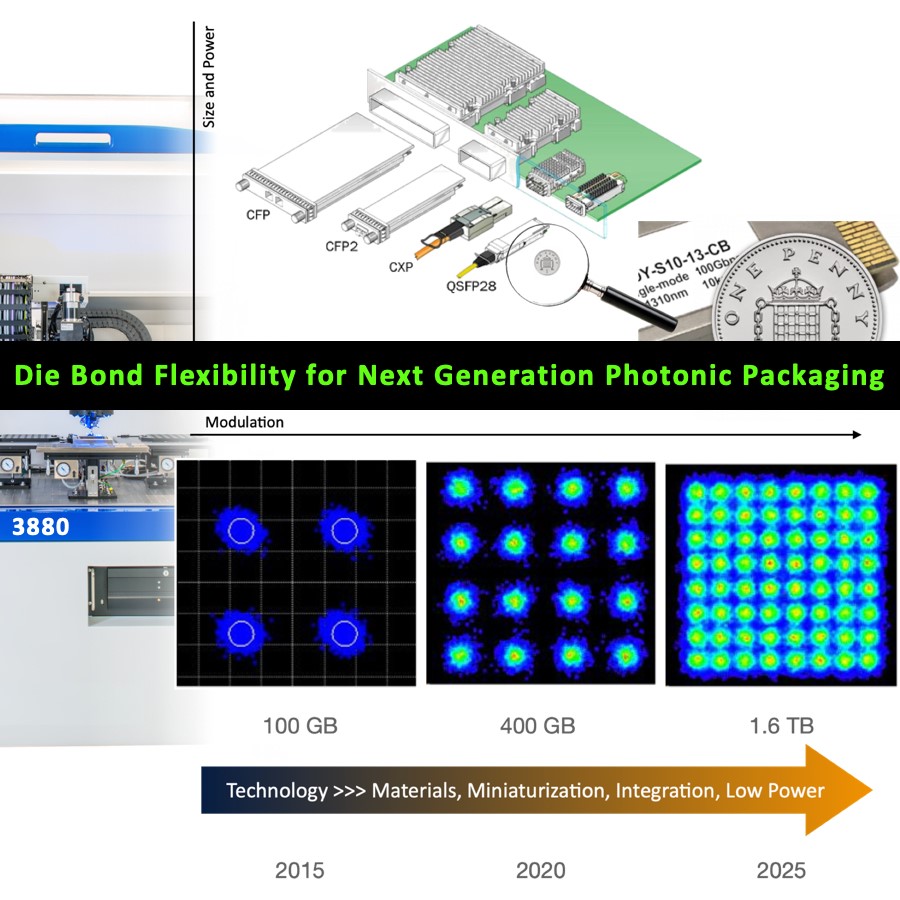

- GaAs/GaN/SiC Die Attach

- Die Attach for Pressure Sensors

- High Intensity LED Attach

- Multilayer Ceramic Capacitors

- CPV Solar Cell Assembly

- High Power Laser Module Assembly

- Copper Clip Soldering

- Hermetic Sealing of IR Image Sensors

- Hermetic Sealing of Hi-Rel Packages

QuikCool™

QuikCool™ is an auxiliary cooling unit designed to rapidly reduce the temperature of the target plate to enable a faster production process. The entire process takes place in one chamber to reduce handling and increase speed of production.

Mid Vacuum

Mid Vacuum option allows the oven to achieve a chamber vacuum level in the range of 10-5 Torr or lower. This option often used for the sealing of the IR Sensors, where specific vacuum level needs to be sealed inside the package for the optimal functionality of the sensor.

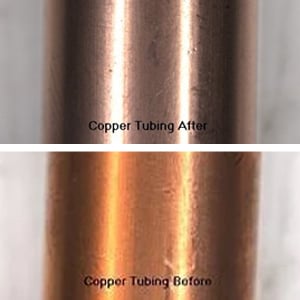

Formic Acid

Built-in formic acid delivery system to reduce surface oxides for high quality wetting. Formic acid is a two-temperature step operation which reacts with the surface oxides at low temperature and then decomposes at higher temperature, leaving a pure metal surface for optimal solder reflow.

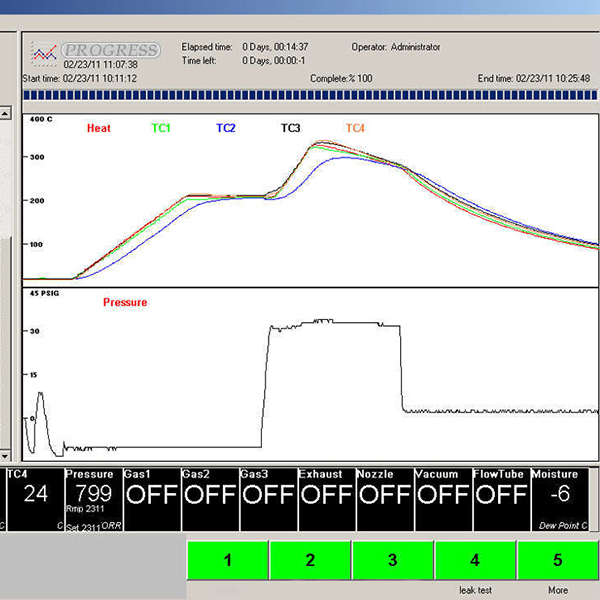

Run Analyzer

Run analyzer provides ability to graphically review data from logged profiles and export data. This includes real-time display of the thermal and pressure profiles as well as the ability to aid in process development by helping identify plating or material changes in your products.

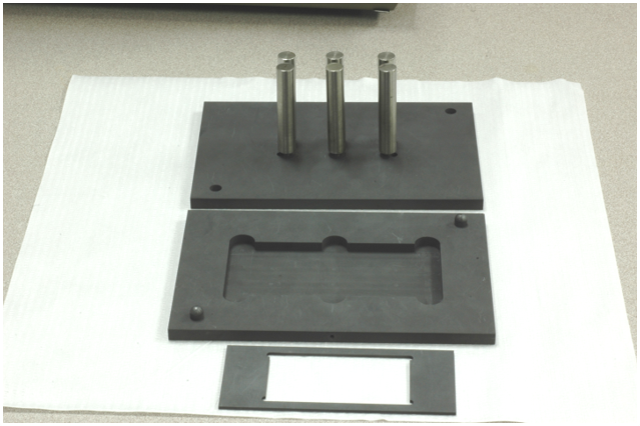

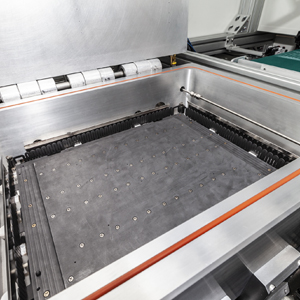

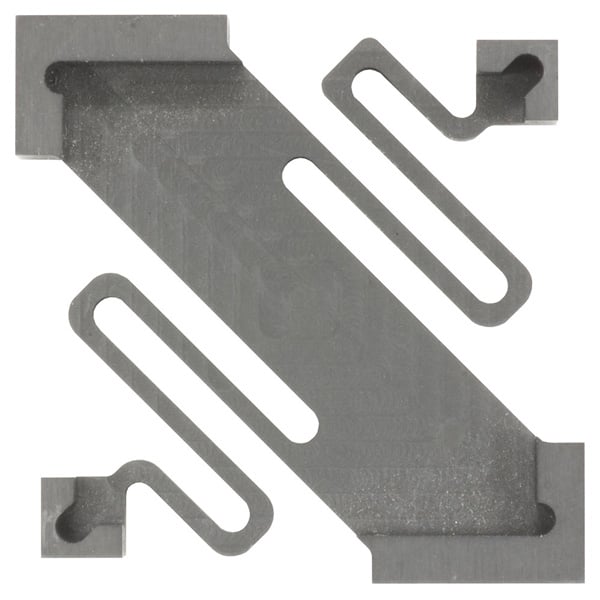

Graphite Tooling – Design and Manufacture

A full selection of products and services to meet your needs for precision graphite products. We combine our extensive inventory of premium graphite materials with engineering and design services, precision machining of graphite, ceramics and metals, and post-machining services such as cleaning, purification, coating and impregnation.

Multi Chamber

Multiple isolated chambers allow for different processes to run simultaneously within a single machine. Combined with the autonomous handling of components across chambers, entire assembly lines for vacuum reflow processes can be condensed into a single environment, controlled and managed from one interface.