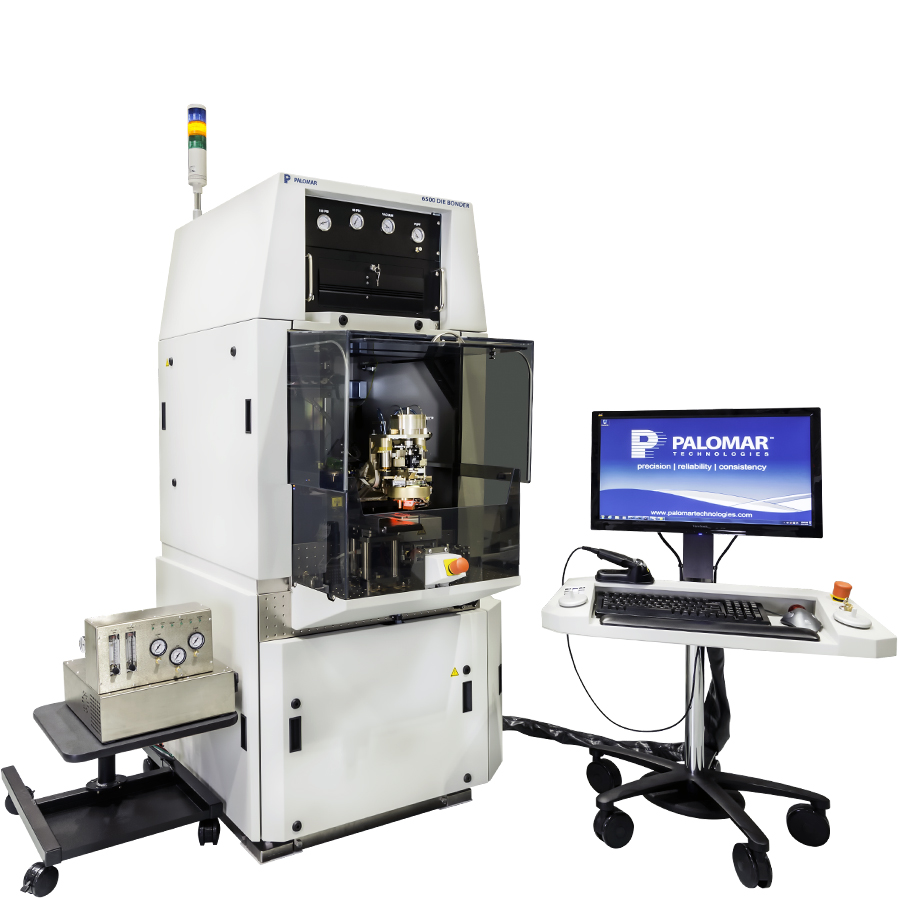

6500 Die Bonder

6500 Die Bonder

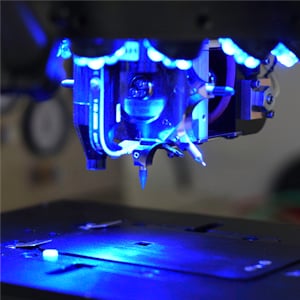

The Palomar 6500 Die Bonder offers a balanced combination of accuracy, speed, and flexibility in a compact system footprint. The 6500 Die Bonder performs ultra-high accuracy eutectic and adhesive placements with cycle times under seven seconds using its four-axis positioning system driven by linear motors gliding over air bearings on a steel based frame.

- P-side down laser diode attachment

- Silicon bench (V-Groove) placement

- High-density RF power transistors

- Ultra-fine pitch hybrid assemblies

- MEMS components

- VCSEL modules

- Data storage

- High-bright/high-power LED arrays

- Optoelectronic packaging

- LED printhead attachment

- Solar concentrator packaging

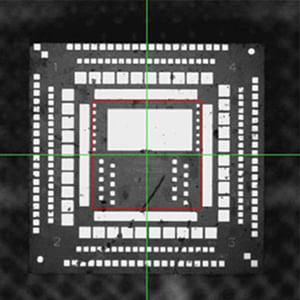

VisionPilot® with Vision Standardization

Utilizes advanced geometric pattern matching technology to reliably and accurately locate parts that are randomly oriented or have greyscale variations by using a set of boundary curves that are not tied to a traditional pixel-grid. Vision Standardization ensure consistency across systems and throughout the lifetime of the machine; reducing process maintenance and maximizing production.

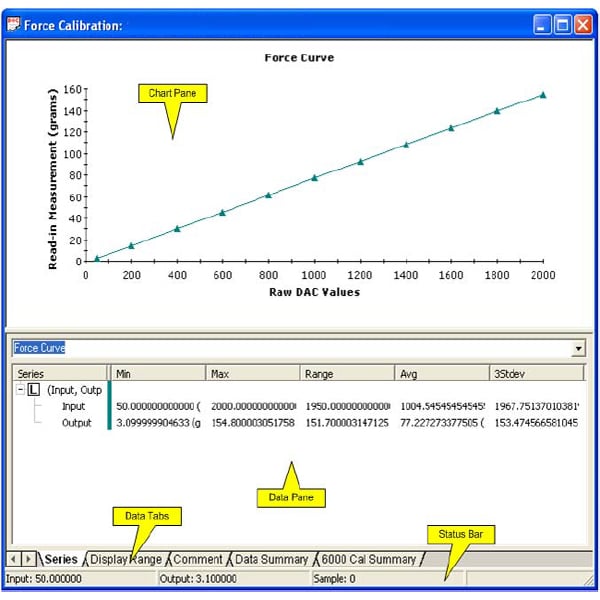

A comprehensive and centralized data management and analysis system that provides machine and process trend monitoring, storage and traceability of data across platforms, and closed loop process control for increased yields and predictive maintenance.

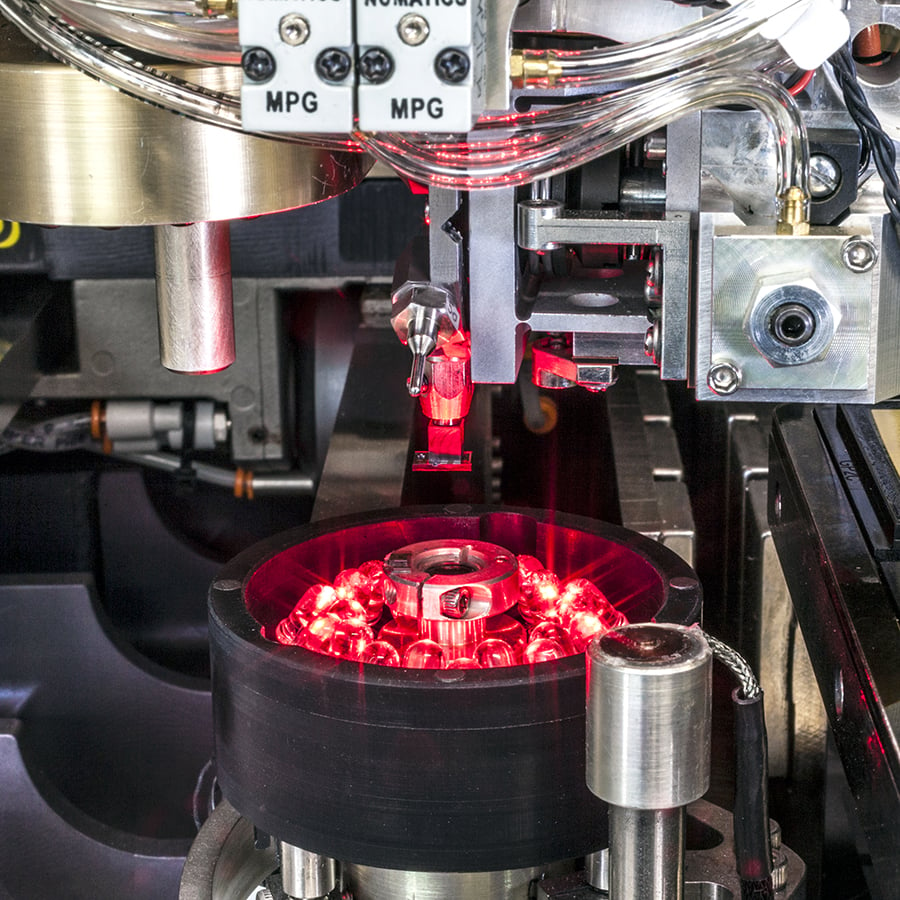

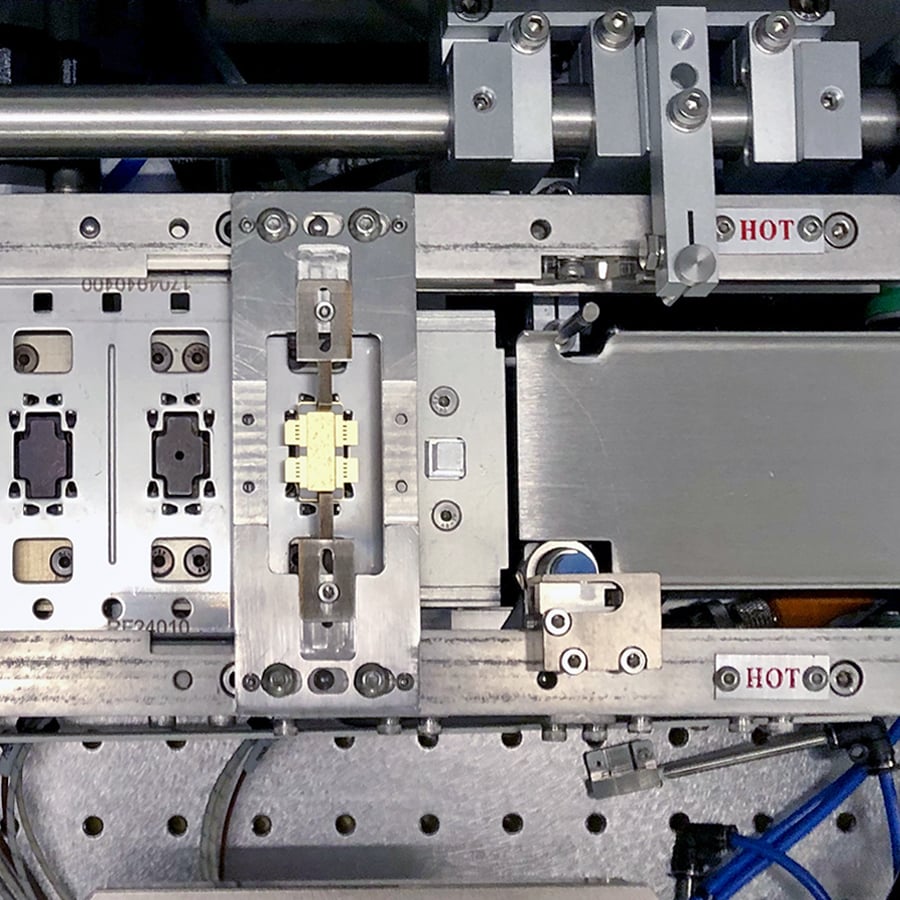

Highly accurate computer-controlled heating solution for solder based applications. Available in several forms ranging from a large surface area model to accommodate all part sizes to a heating source incorporated into the tool itself for localized heating.

Dispensing Solutions

Dispensing solutions range from the highly consistent Musashi Jetter which is not only surface height and temperature independent but also the highest throughput option for small controlled dispensing and the perfect option for 5G applications to the precisely controlled Nordson Micro Dot time-pressure solution which is capable of dispensing all the way down to “0.006 diameter dots.

Automated Handler System

Automated inline handlers and conveyor systems to seamlessly bring parts in and out of the workspace. Custom designed for all process to fit all components and even apply heat for both die and wire applications. Built with integration in mind for fully automatic assembly lines that can include all of our bonders.

UV Systems

A wide variety of options for UV sources ranging from custom designed stages with mirrored surfaces and actuating covers for maximum UV exposure to head mounted UV sources with programmable intensities that can provide the perfect cure profile for the best results.

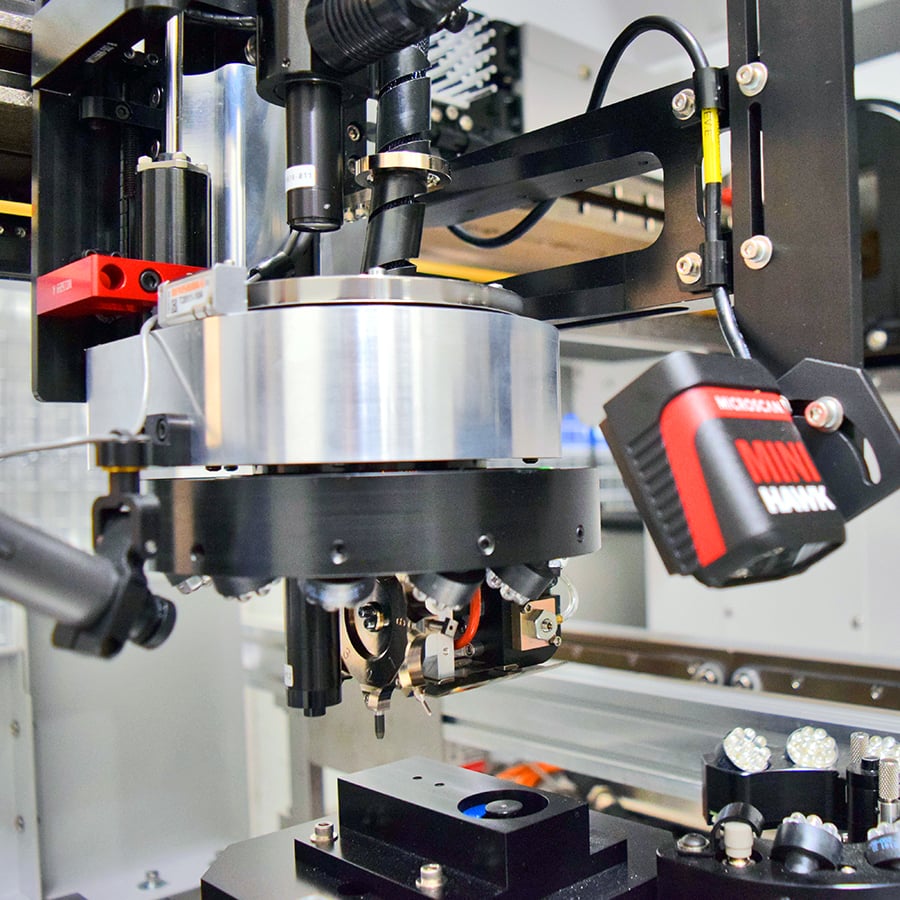

Identification Systems

Seamless integration with all types of barcode scanners, from 2D to 3D, which can be mounted on the bond head or integrated within the workspace of our bonders. Characters on chips can even be read with the onboard vision system. All identification information is tracked and collected in a report for easy review.