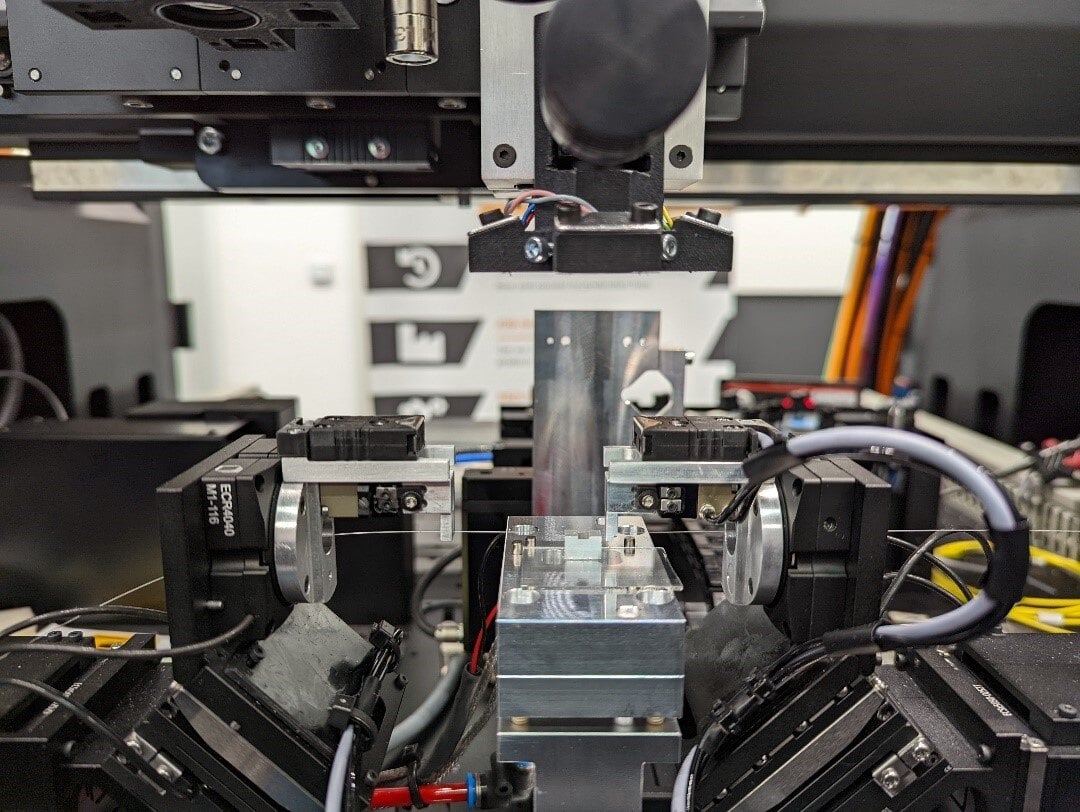

Navigating Back-End Manufacturing Pain Points in Micro-Optoelectronics

Back-end manufacturing in micro-optoelectronics, though representing only ~10% of the total investment to bring a product to market, is a ...

Posted by Palomar Technologies MarCom Team on