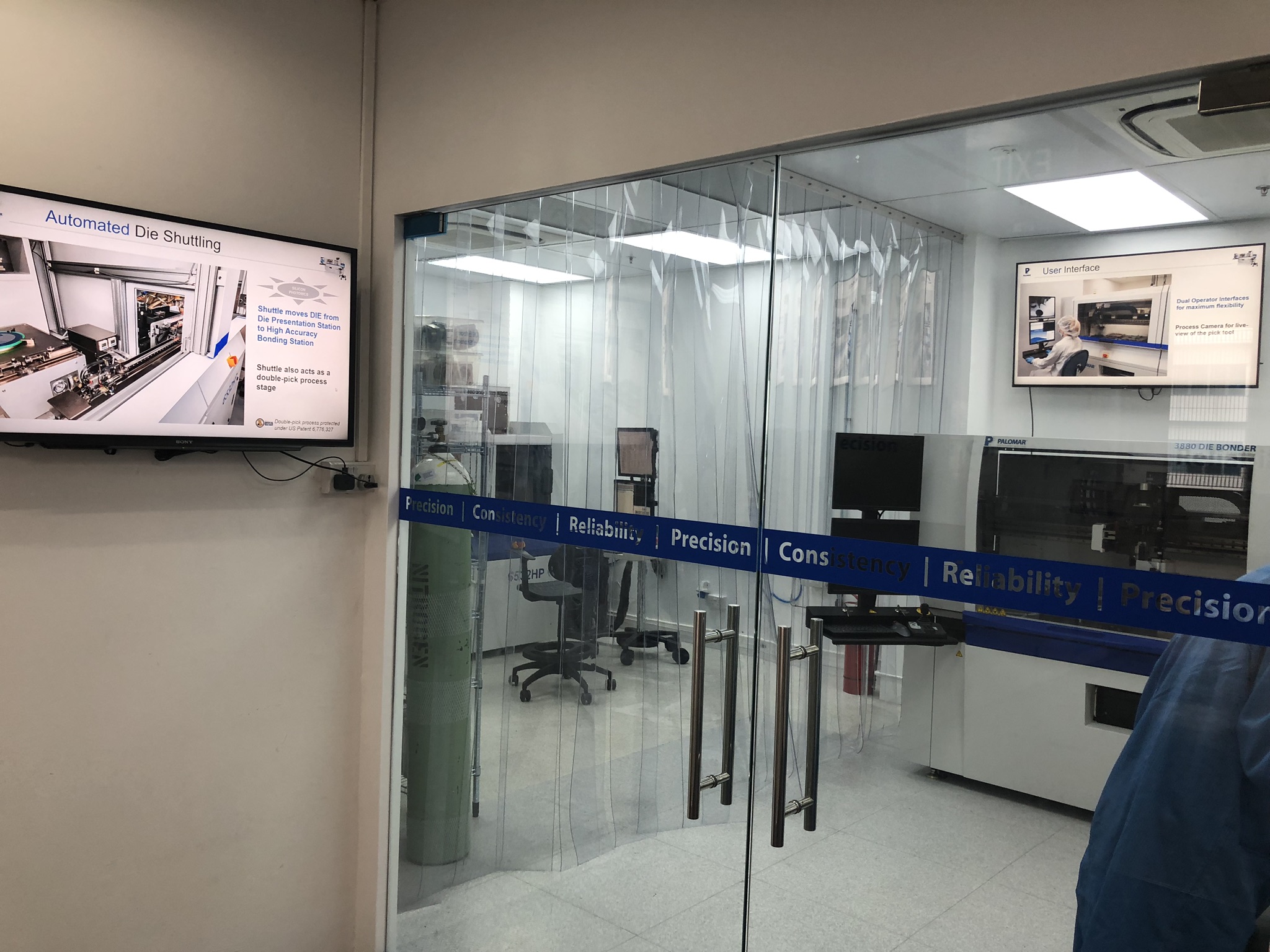

Palomar Technologies 3880-II Die Bonder honored by 2022 Military + Aerospace Electronics Innovators Awards

Carlsbad, CA – September 8, 2022 – Palomar Technologies, a global leader in delivering total process solutions for advanced photonics and ...

Posted by Palomar Technologies MarCom Team on