Palomar Technologies wire bonders have for many years used voice coil technology to drive the bond heads. The decision to go to voice coil technology was made because it is simply a higher level of technology: more sophisticated and superior in comparison to other types of technology such as solenoid or piezo.

The decision to go to voice coil technology was made with careful consideration to competing technologies such as solenoid or piezo drive systems, with the voice coil technology ultimately winning out. The primary considerations that made the voice coil actuator a superior design choice were its robustness, its low complexity, and its capability. While a solenoid actuator is limited in forcing direction and a piezo solution requires complicated, sensitive electrical drive systems, the voice coil actuator occupies a sweet spot of functionality and simplicity.

Some of the unique features of voice coil technology:

- The voice coil actuator tends to have a lower force constant in comparison to a piezo drive system, leading to more force command resolution.

- Solenoids tend to be higher force for the same current.

- Voice coils, compared to solenoids, give better force sensitivity/control and the ability to drive bi-directionally.

- Voice coils, compared to piezos, would not need complicated drive electronics, would not be temperature or drift sensitive, and would be far easier to set up.

- Greater force precision; smaller force increments with greater control.

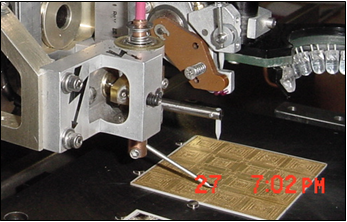

On the 9000 Wedge Bonder, bond force is applied using a robust, low maintenance voice coil bond head. The compound Z axis (Zcourse + Zfine) results in much more controlled bond force. The low mass Zfine is a voice coil actuated axis with 0.1um encoder resolution which allows fine control of Z position.

On the 9000 Wedge Bonder, bond force is applied using a robust, low maintenance voice coil bond head. The compound Z axis (Zcourse + Zfine) results in much more controlled bond force. The low mass Zfine is a voice coil actuated axis with 0.1um encoder resolution which allows fine control of Z position.

The 8000i Au Wire/Ball Bonder and Bumper uses a voice coil bond head. It also has a compound Z axis (Zrotary + Zlinear) which in combination results in much more controlled bond force. This optimizes delivery of force and ultrasonics, enabling repeatable ball formation and improved shear strength and loop strength.

The 8000i Au Wire/Ball Bonder and Bumper uses a voice coil bond head. It also has a compound Z axis (Zrotary + Zlinear) which in combination results in much more controlled bond force. This optimizes delivery of force and ultrasonics, enabling repeatable ball formation and improved shear strength and loop strength.

Why Precision Control is important

Especially in wire bonding where the bond (stick) is generated by a combination of heat, force, and ultrasonics (or in cases of Al wire just force and ultrasonics), a frequent challenge customers face is pad cracking due to incorrect bond force application and a combination of the all of the elements that make for a “good bond”. In ball bumping/wire bonding, desired bump shape, repeatable planarity of bump, and strong loop strength are also results of precision control. As it applies to wedge bonding, fragile bond pads or, in general, applications where there is difficulty in achieving repeatable wire bonds, precision control is paramount. Voice coils overall have better sensitivity of force application. If you are experiencing pad cracking, the 9000 Wedge Bonder is the right machine to solve this problem.

Download these resources for more information:

| 9000 Wedge Bonder Data Sheet |

8000i Wire Bonder Data Sheet |

Improved Wire Bond Reliability eBook |

|

|

|

_____

Rich Hueners

Vice President of Sales & Marketing

Palomar Technologies, Inc.