Bond Data Miner

Bond Data Miner

Bond Data Miner is a comprehensive and centralized data management and analysis system that provides machine and process trend monitoring for increased utilization and yields, along with predictive maintenance.

- Large complex hybrids

- HB/HP LED arrays

- Optoelectronic packaging

- Microwave modules

- RF packages

- Hybrid microcircuits

- MEMS / MOEMS

- VCSEL, PD, DFB Laser, Lens Attach

- Solid state lasers

- RF GaN 5G power amplifiers

- RF power amplifier

Real-time Feedback

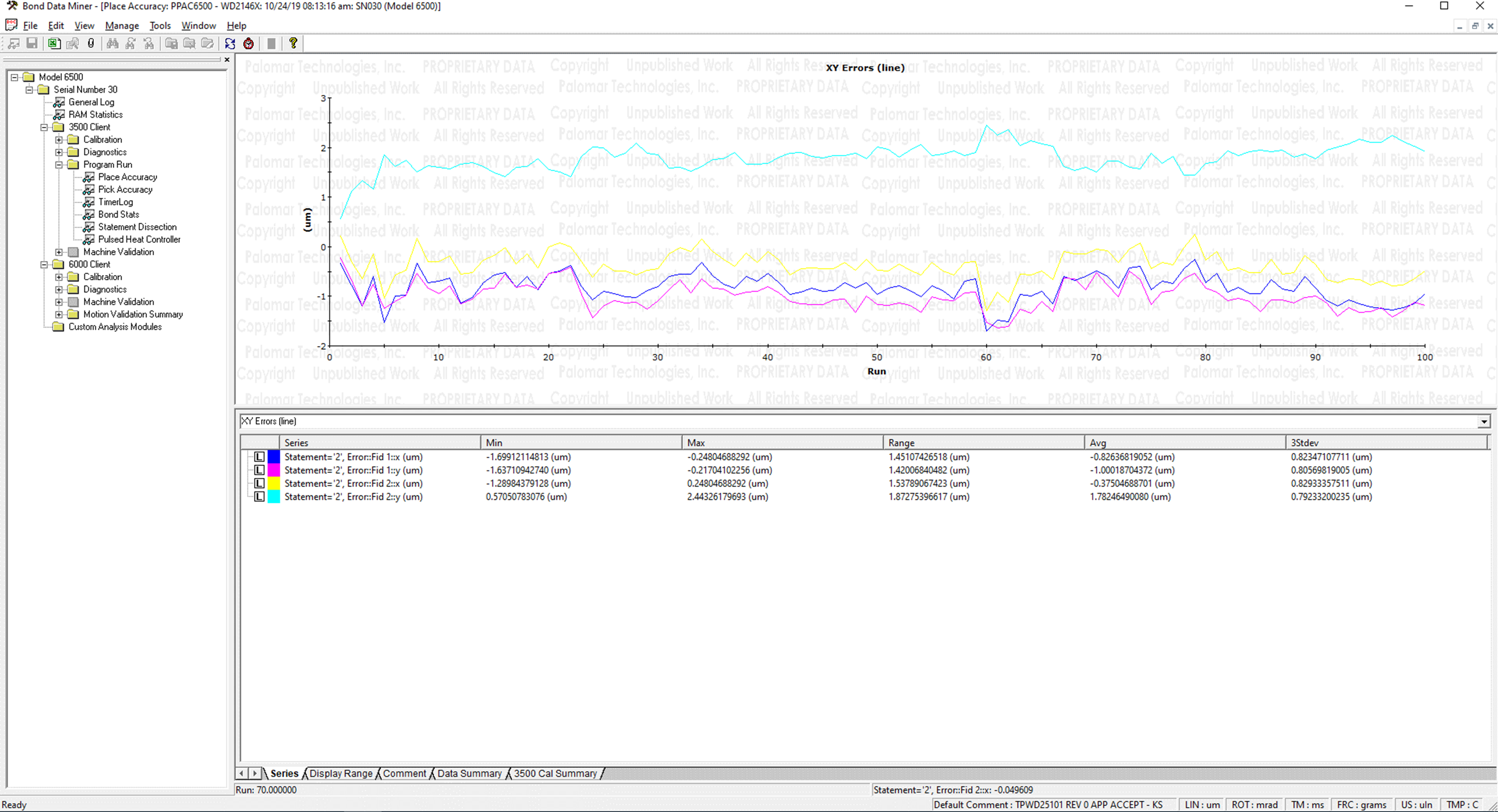

Data tracking and analysis presented during machine operation. Active feedback can be displayed for the current process in the form of placement accuracy, bond deformation and more.

Condense Data Across Multiple Systems

The software offers a single access point to pool not only multiple types of data but also data across other machines and model types for analysis and tracking. Compare process history across systems to optimize performance.

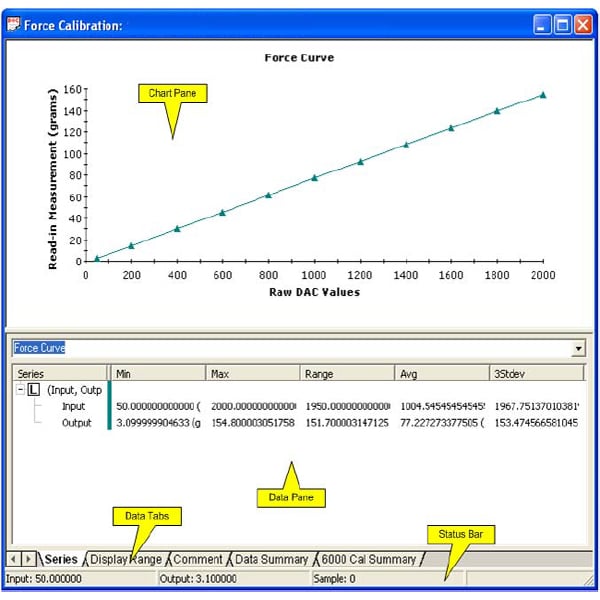

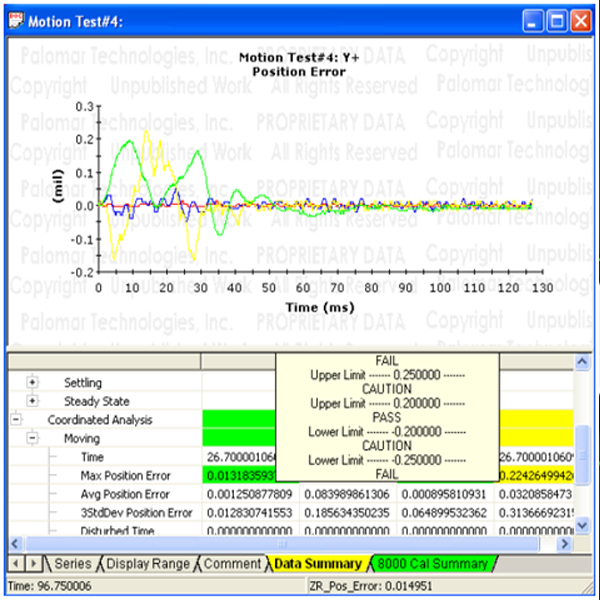

In-Depth Data Analysis

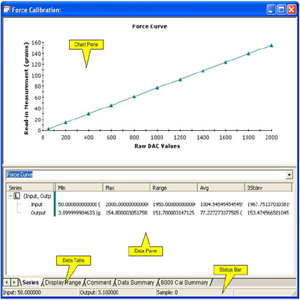

Trend data across multiple diagnostics, calibrations, and process runs to predict preventive maintenance and analyze machine conditions. Dissect and filter comprehensive diagnostics and run history with ease for powerful and targeted information.

Inventory and Bonding Stats

Catalogue bonding stats such as how many bonds a particular tool has made alongside tracking what specific components have been used for which assemblies. Keep records of all relevant information needed to maintain quality as a high priority.