Due to the accuracy and flexibility of our systems (along with the decades of experience and knowledge of our staff), we often get to work with companies on the leading edge of processes and products. We have shared in the past that we are often called upon to do the “hard stuff”. This can be challenging, but at the same time very rewarding. So how do we tackle this "hard stuff"?

The Journey Beings with Assembly Services

Often the initial path the customer chooses is our Assembly Services division. The customer provides a statement of work along with drawings, pictures, sketches, etc. in order to help us understand the process and their product. In many cases, the customer may not have the interconnect-packaging experience, but is looking for more of a risk assessment. Often we can suggest a path where we run tests, experiments, and prototype builds. We can also get a good estimate of what types of throughput and yields they can expect. This process can take weeks or years depending on the complexity of product and process. Assembly Services gives the customer the peace of mind that allows them to budget and plan for volume production.

System Flexibility

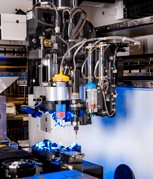

The flexibility of our systems allows for different paths and solutions. For example,  let’s say our customer needs high-accuracy die attach using some type of epoxy—epoxy type and viscosity unknown. Our 3880 Die Bonder has accuracy of 5um while having the ability to use different types of epoxy dispense, digital pumps, auger

let’s say our customer needs high-accuracy die attach using some type of epoxy—epoxy type and viscosity unknown. Our 3880 Die Bonder has accuracy of 5um while having the ability to use different types of epoxy dispense, digital pumps, auger

pumps, time pressure, and daubing. In addition, the system has the capability to perform UV cure, eliminating the complexity of transferring the part to an additional system, and allowing the part to be held during the cure to avoid part settling or movement.

If it’s a eutectic process that your product requires, the 3880 also has a variety of solutions, such as our Pulsed Heat System which allows for programmable and accurate temperature profiles during the reflow. There are also high-temperature stages and “scrub” capabilities for doing other processes, such as direct silicon to gold attach. There is also the capability of using a heated tool in conjunction with a heated stage.

All of these epoxy and eutectic applications can be on one system, ready to program and implement. This makes the 3880 a very versatile and flexible tool that can be used in an R&D environment, or in volume production.

To finish your packaging with the interconnect, Palomar offers our deep access, large work area 8000i Wire Bonder and Ball Bumper, as well as our ultra-flexible 9000 Wedge Bonder. These systems provide flexibility on wire size, wire type, pitch, and looping, as well as a variety of interconnects such as chain bonding, stand-off stitch, and security bonding.

----

Dale Perry

Regional Account Manager, Eastern America

Palomar Technologies, Inc.

Download these resources for more information:

| Assembly Services Data Sheet  |

||

| 3880 Die Bonder Data Sheet  |

8000i Wire Bonder Data Sheet  |

9000 Wedge Bonder Data Sheet  |