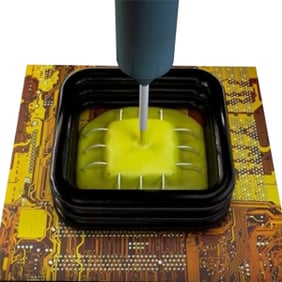

Epoxy die attach, sometimes referred to as epoxy die bonding, is the most commonly used die attach method. Whether dispensed or daubed via single pin or stamp transfer, it is a more cost-effective solution compared to eutectic bonding; this is due to lower material and process costs.

Typical epoxy die attach applications include: simple transistors, encapsulation of wire bonds, LED attachment, MCMs, and complex hybrids. Hybrid microcircuits, in particular, have seen tremendous growth in popularity due to their built-in flexibility and small package sizes. Aerospace and defense, medical, and optoelectronic device manufacturers have integrated the hybrid package to achieve multiple-need and multi-performance requirements.

hybrids. Hybrid microcircuits, in particular, have seen tremendous growth in popularity due to their built-in flexibility and small package sizes. Aerospace and defense, medical, and optoelectronic device manufacturers have integrated the hybrid package to achieve multiple-need and multi-performance requirements.

With rapid time-to-market needs, automating the packaging process has become more critical than ever before. Epoxy die attach is a consistent, reliable, and flexible form of component attach. Automated epoxy dispense systems have kept up with these advances by maintaining a high level of control, handling, and integration through sophisticated process control software.

To learn more about epoxy daubing, epoxy dispensing and the conductive epoxy process, read our technical article: https://www.palomartechnologies.com/automatic-epoxy-die-attach-paper.

Also, download these resources for more information on solutions for epoxy die bonding:

| 3880 Die Bonder Brochure | 6500 Die Bonder Brochure |

|

|

----

Anders Schmidt

Applications Engineer II

Palomar Technologies, Inc.