3130 Vacuum Pressure Furnace

3130 Vacuum Pressure Furnace

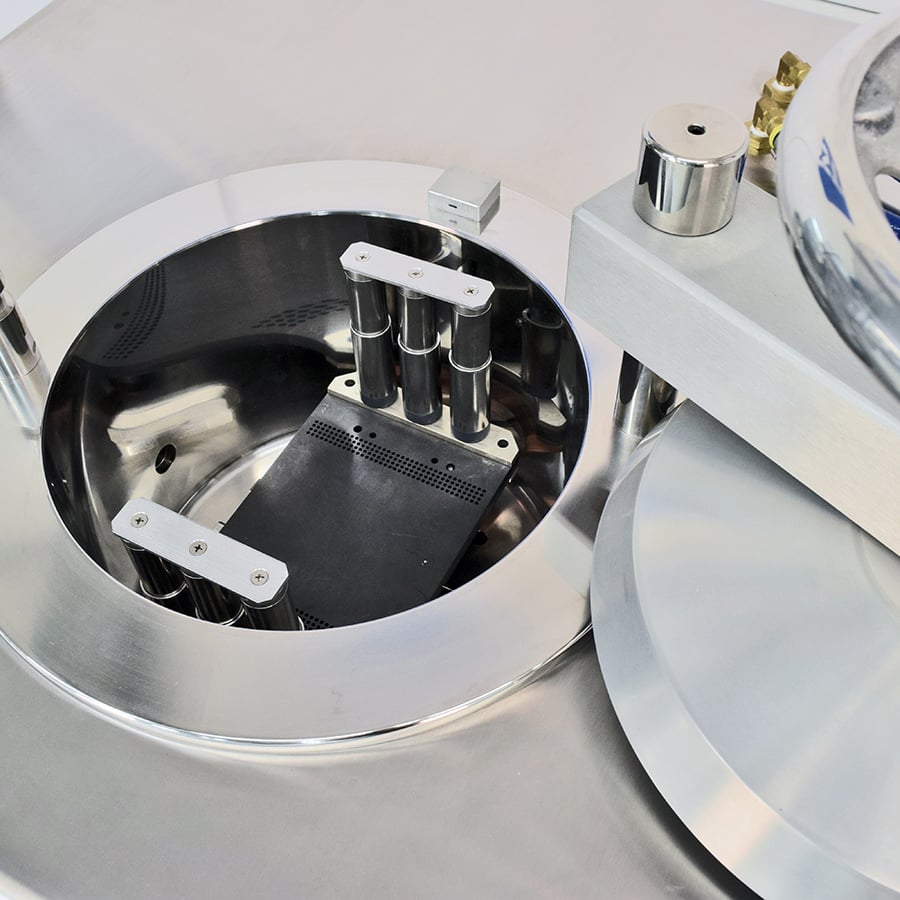

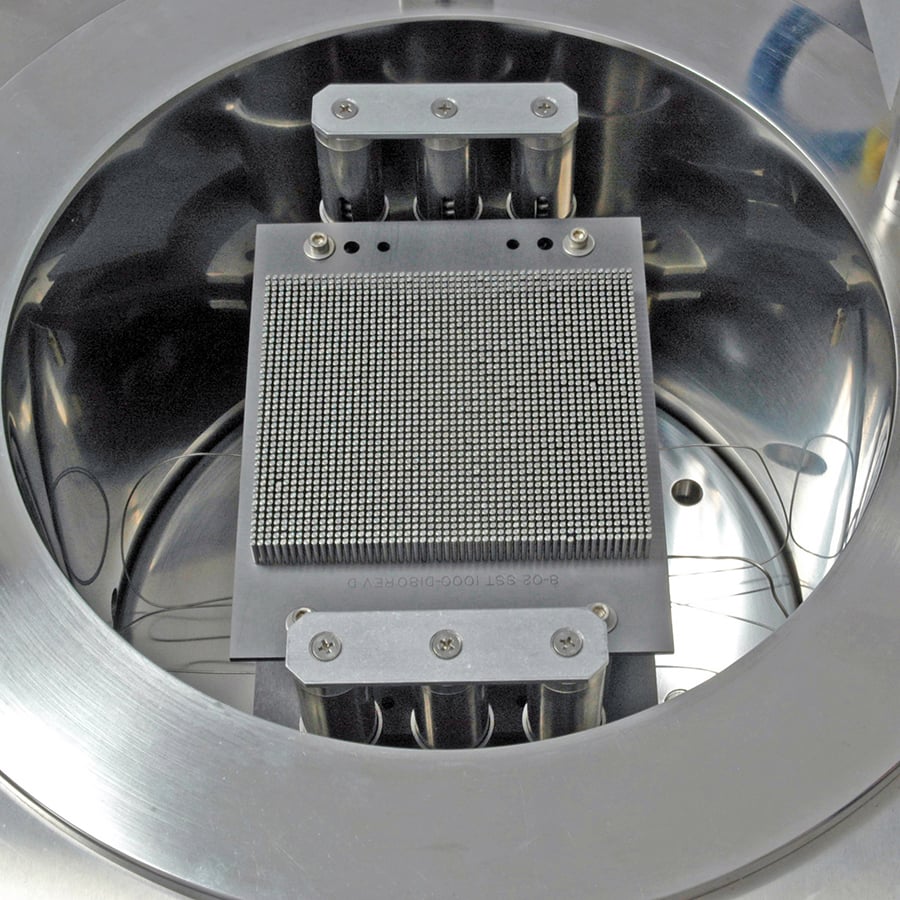

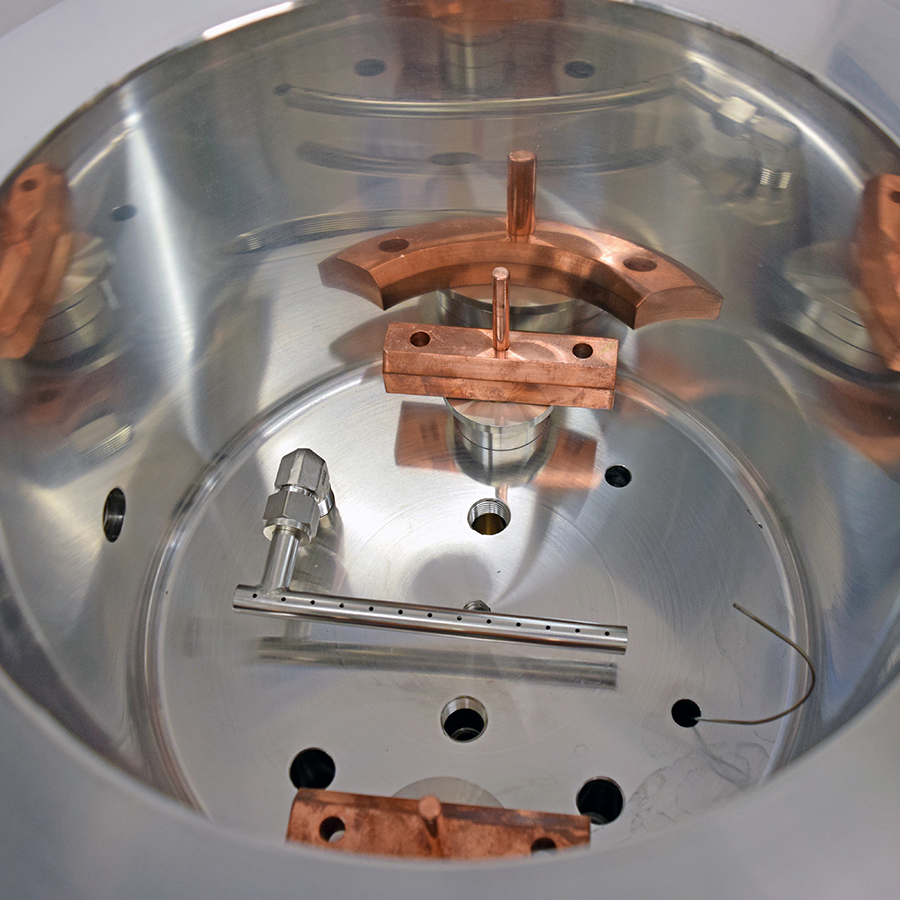

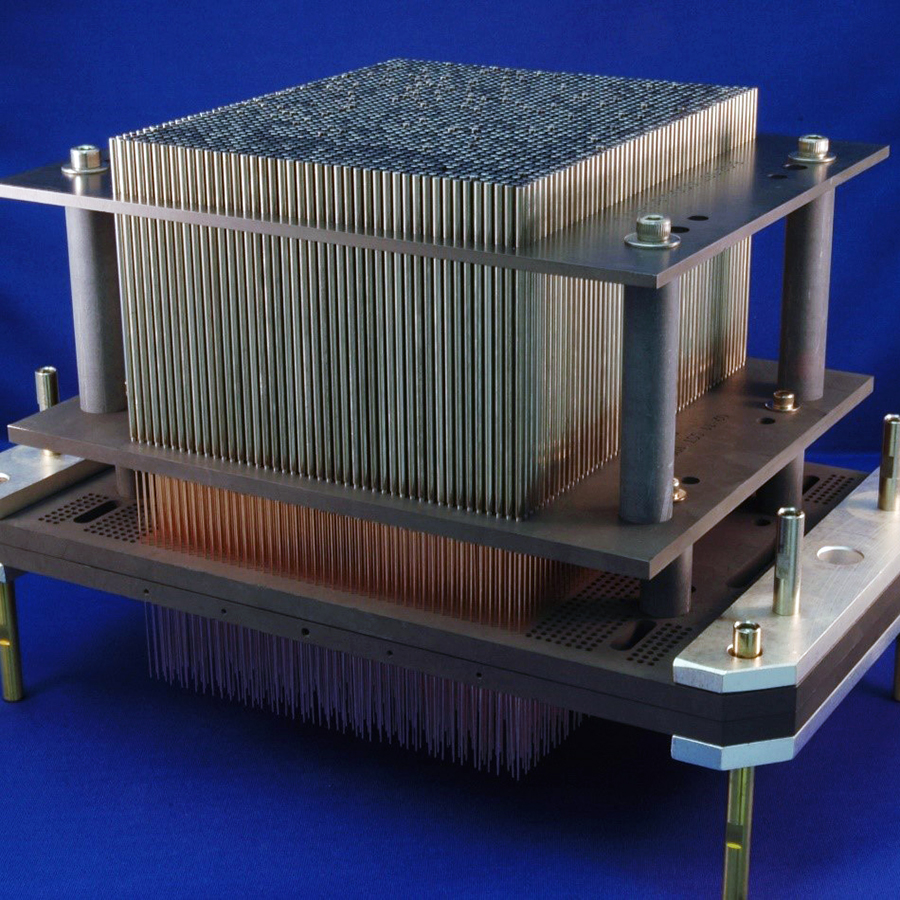

The SST 3130 is a deep chamber resistive heat vacuum and pressure furnace for void free solder joints without the use of flux, resulting in high reliability electronic components. The 3130 provides precise automatic control of heating to 500°C (1000°C optional) and cooling in an inert gas environment from vacuum levels of below 50 millitorr to pressures exceeding 50 psig. The system is used in both production and research environments for flux-free soldering, brazing, annealing, and glass sealing of components and packages for microelectronic applications.

- Fiber Optic Laser Package Assembly

- GaAs/GaN die attach

- Glass to metal seals

- Brazing

- Pressure sensors

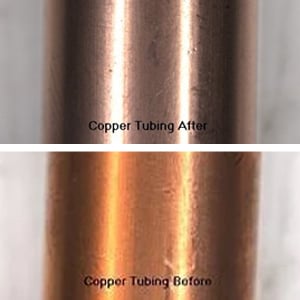

Formic Acid

Built-in formic acid delivery system to reduce surface oxides for high quality wetting. Formic acid is a two-temperature step operation which reacts with the surface oxides at low temperature and then decomposes at higher temperature, leaving a pure metal surface for optimal solder reflow.

Extended Temperature

Extended temperature enables the system to reach temperatures up to 1000C. Several key applications such as brazing, glass to metal sealing, or glass to glass sealing require high temperatures which can be achieved through Extended Temperature.

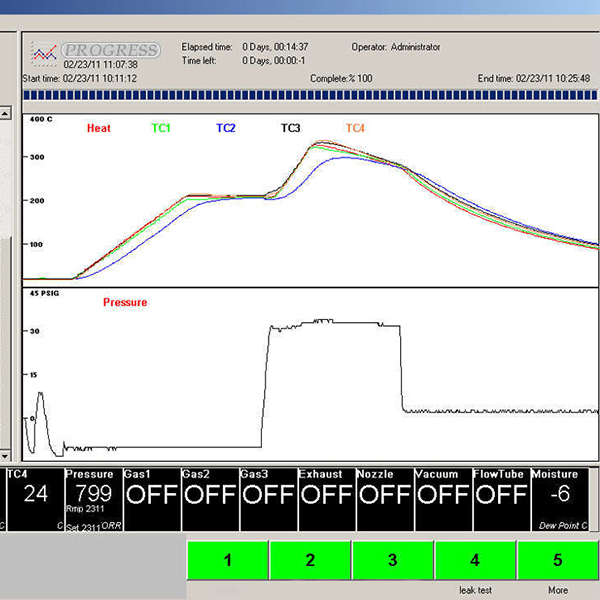

Run Analyzer

Run analyzer provides ability to graphically review data from logged profiles and export data. This includes real-time display of the thermal and pressure profiles as well as the ability to aid in process development by helping identify plating or material changes in your products.

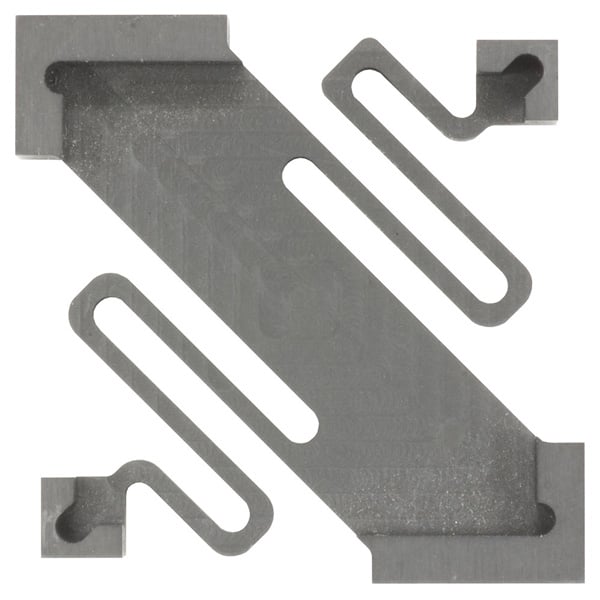

Graphite Tooling – Design and Manufacture

A full selection of products and services to meet your needs for precision graphite products. We combine our extensive inventory of premium graphite materials with engineering and design services, precision machining of graphite, ceramics and metals, and post-machining services such as cleaning, purification, coating and impregnation.