Carlsbad, CA – May 19, 2015 – Palomar Technologies, the world-leading provider of precision microelectronics and optoelectronic packaging systems, announced today they will be one of over 550 exhibitors at the International Microwave Symposium (IMS) at booth #2517 on May 19-21 in Phoenix, Arizona. IMS is “the premier annual international meeting for technologists involved in all aspects of microwave theory and practice”. IMS stated, “It is the synergy of the Exhibition in conjunction with the Technical Symposia that makes Microwave Week the premiere international gathering for everyone involved in technologies associated with RF, microwave, millimeter wave, and THz frequencies”.

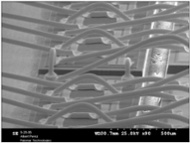

Automated wire bonders were introduced in the early 1980s. At that time, the majority of interconnects were made using aluminum wire. As the need for high reliability increased, gold wire became more common. As package densities increased, wire interconnect bond pitches decreased. The initial solution to fine pitch was wedge bonding because the wedge tool design allows wires to be bonded in close proximity (side-to-side).

The RF and microwave markets are characterized by lower volume and higher mix when compared to semiconductor packaging. This requires different levels of manual and automatic assembly process steps depending on product and manufacturing maturity. Suppliers can help customers through the various stages of manufacturing automation by providing manual, semi-automatic, and fully automatic islands and lines of equipment and process.

Although there is continued effort in the semiconductor packaging industry to reduce package size along with the never-ending pursuit of cost savings, there remain a significant number of applications requiring a wildly different set of capabilities for die and wire bonding.

Download "RF, Microwave, and Optoelectronic Packaging Die and Wire Bonding Case Studies" to take a deeper look at varying die attach and wire bonding requirements for emerging applications in the RF and microwave markets. The paper discusses three case studies:

- RF-SOE Product (High Accuracy Die Bond + Semi/Automatic Wire Bond)

- Optoelectronic Printer Product (Ultra Accuracy Die Bond)

- High Brightness LED Matrix Product (High Accuracy Die + Semi/Auto Chain Wire)

About Palomar Technologies:

Palomar Technologies, a former subsidiary of Hughes Aircraft, is the global leader of automated high-accuracy, large work area die attach and wire bond equipment and precision contract assembly services. Customers utilize the products, services and solutions from Palomar Technologies to meet their needs for optoelectronic packaging, complex hybrid assembly and micron-level component attachment. For more information, visit www.palomartechnologies.com.

Download these resources for more information:

| RF, Microwave, and Optoelectronic Packaging Die and Wire Bonding Case Studies | 9000 Data Sheet |

|

|

----

Katie Finney

Marketing Specialist

Palomar Technologies, Inc.