Although Palomar Technologies belongs to a niche industry, there are multiple markets in which we serve. Some of those markets include microwave, defense, automotive, and aerospace (just to name a few). Recently, Palomar attended two technical conferences (CTIA Super Mobility and MEPTEC/SMTA/iNEMI Medical Electronics Symposium) targeting two of these unique markets: wireless and medical technology.

The Growing Wireless Market

CTIA is a massive trade show held every year at the Sands Convention Center in Las Vegas, Nevada with over 35,000 attending and over 1,100 exhibitors focusing on all things wireless. Everything from cell phone cases and chargers, to antennae, wireless infrastructure, cooling, alternate power and drones are featured at this trade show.

Where do we fit in the wireless market? Up to 85% of all base station power amplifiers world-wide have been manufactured on fully automatic 3500 and 3800 series eutectic die bonders.

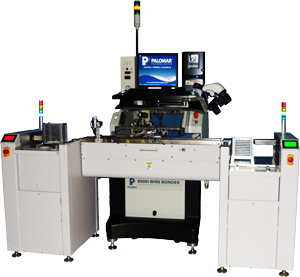

Many of these power amp modules require very precise and repeatable wire bonding. Most accomplish this with automatic wedge bonders, such as our recently launched 9000 Wedge Bonder. With its large area deep access capability, the 9000 can dial-in precision looping that exceeds all looping requirements. It can also handle both round wire and ribbon. Along with its 90 degree clamping allowing for very deep access, its 45-60 degree clamping makes for high throughput.

Wedge Emulation

Some people are converting to “wedge emulation” using a ball bonder, such as our 8000i, which can also generate laser loops. Some reasons one may choose ball bonding for microelectronic packaging are throughput and yield. This is a very mature process and is well understood. Ball bonders will always be faster than wedge bonders, and they also have the ability to yield packages with a higher process capability (Cpk).

The image below is an example of a package that required multiple sizes of round wire when wedge bonded, but could tune and operate with a single size of round wire when ball bonded. Loop height repeatability in both cases allows for less than one wire diameter variation (or ~12-17 micron total variation). Loop sway is a negative; the wires must never touch even if they are interconnecting the same die pads.

The very short, low loops to the left of the center actually bridge over active metallization. There are many of them, and it only takes one to cause a short and kill the device when powered up. A process with 100% yield is vital.

Medical Device Packaging

The MEPTEC/SMTA/iNEMI Medical Electronics Symposium is held at the Marylhurst University just outside of Portland, Oregon each year just prior to the Autumnal equinox. A large number of medical device packaging engineers and executives attend this technical conference.

When ultra-high resolution and repeatability of device packaging systems that are measured in microns combine with the maturing designs for wireless monitoring, connectivity, and control, advanced medical packaging can be amazing. Each year Palomar Technologies exhibits at this technical conference to share advanced packaging capabilities via our high-reliability systems and Assembly Services. We have been working with all the major medical solutions providers for over 25 years, dating back to when we were a part of Hughes Aircraft. Please join us at one of the dozens of technical conferences that we exhibit at and attend worldwide each year!

Download these resources for more information:

----

Bradley Benton

Regional Account Manager, Western Americas

Palomar Technologies, Inc.