Each year we can look back and try to reconcile our good and bad projects. If we focus on the good, we will find the possibility of future trends. Not only will we find better, smaller, faster, cheaper aspects, but also which of these are trending and for what reasons. At Palomar Technologies we get involved in a very wide range of applications. While we cannot discuss any single one in specific, we can review the general technology paths customers from across many markets pursue.

An easy mark is the ever pervasive trend for higher accuracy die attach or component placement. Today’s goals seem to lean towards applications in the 3-5 micron space. In the future, it is safe to say that the range will only move towards higher and higher final placement accuracies (FPA). This is the case for both epoxy attachment and eutectic attachment, from single die attach processes, to flip chip die attach, or even stacked die applications. Circuits built around packages with die attached with extreme precision and repeatability can generate better results without needing to compensate at wire bond.

There are a number of ways to tackle these requirements: complex vision algorithms, environmental controls, ultra-high resolution and repeatability positioning systems. In the end, one of the largest items in the error bucket tends to happen after the placement has been accomplished. In this scenario, we look towards “In-Sutu” processes such as: hot-gas, UV, and Pulse Heat eutectic processes.Palomar’s recently launched 3880 Die Bonder affords all of these technologies and more, driving the FPA downward.

Positional accuracy for wire bonding is more a function of the wire bond tool itself, but loop height and shape requirements are constantly demanding more resolution and repeatability. These trends require better wire handling, exotic loop shape profiling, and very fine control of a large range of 3D coordinated bond tool motions. Palomar Technologies addresses each of these issues and continues to develop new wire profiles, shapes, and loop modes. High frequency devices require very accurate wire profiles.

Larger modules require larger working envelopes. As packages become deeper each year, they require very deep access capability. Palomar’s 8000i Wire Bonder can use 0.437”, 0.625”, and even 0.750” capillaries allowing for very deep access ball bonding. When combined with Stand-off Stitch processes, we can generate mid span breaks through the entire series tool lengths.

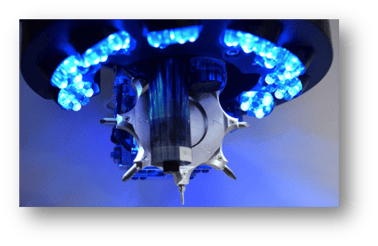

Our new 9000 Wedge Bonder allows for low profile bonding with a 45-60° wire clamp, or very deep access with a 90° wire feed and clamp. Ribbon bonding has been a growth market for 15 years and in 2016 will see plenty of it as microwave module builds continue to grow. Base station power amplifiers, MM wave adaptive breaking and collision avoidance for the auto industry, both commercial and defense radars, and point to point high bandwidth system markets are all growing rapidly.

Over the last few years we have seen an increasing demand for Assembly Services. These services can stand on their own (as a CM) or can be used in conjunction with a capital equipment purchase. For those looking to acquire a system for in-house builds, working with our Assembly Services group can eliminate practically every unknown such as actual yields, real throughput, and even tooling robustness. This path provides risk mitigation at its finest as we are building actual production parts. These findings can be done concurrently with the system builds, allowing for a seamless transition from our Assembly Services to full production at a customer’s facility.

One last trend is the ever lasting desire for higher quality packages. Palomar constantly strives to generate new equipment and processes that facilitate higher quality builds. Proper wire path handling, stand-off stitch processes, and even complete process characterization and process optimization through our experts in Assembly Services are some of our tools to provide those solutions.

Cheers to high quality packaging in 2016!

| Automated Eutectic Die Attach Paper |

9000 Wedge Bonder Data Sheet |

Guide to Modern Wedge Bonding eBook |

|

|

|

-------------

Bradley Benton

Regional Account Manager, Western Americas

Palomar Technologies, Inc.