Last month, we announced the latest addition to the Palomar suite of die attach and wire bonding solutions. This new machine is called the 3880 Die Bonder. For current Palomar 3800 Die Bonder customers, this model looks aesthetically similar but has many new and improved features, most notably on the bond head itself.

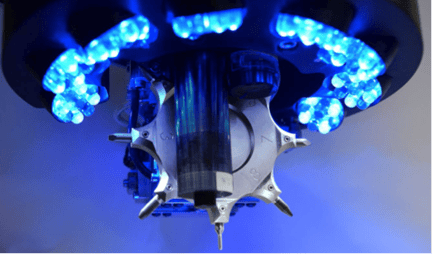

Tool Turret Technology

In the early 1990s, Palomar developed the “tool turret” design which has become standard on all of our die bonders. This tool turret is outfitted with 8 tools and designed for customers who require maximum flexibility while maintaining throughput and yield. Why is the 8 tool turret important?:

- It provides an automated tool change with pre-calibrated and programmed tools for customers who have applications with multiple die types.

- It enables increased throughput (as compared to single tool machines) for applications that have multiple processes, such as: epoxy die attach, eutectic die attach, and pick and place. The 3880 Die Bonder can peform all of these functions quickly and in a single pass--without having to stop the bonder process to change tools from a tool bank or manually.

- Reliability and precision are maximized with a tool turret changing tools. If you have to change tools manually or by using a tool bank, there is a greater chance of error due to the additional steps taken and mechanical interfaces required to change tools.

- The theta resolution is 20 times better than its closest competitor. Specifically, Palomar’s theta resolution is 0.00023 degree compared to the nearest competitor at 0.0045 degree.

- An optional feature that both the Palomar 3500 series (1991-2010) and Palomar 3800 (2010-2015) had long offered was a bi-directional tool turret, which dramatically increases speed for customers in 24/7 or high production environments.

Improved Bond Head and Tool Turret Peformance

While the 3500 series and 3800 Die Bonders are excellent machines that are still in production around the world today, we saw there were many areas where we could improve our technology. We designed the 3880 Die Bonder by keeping the tool turret idea and maintaining 8 tools. Several new features were added to improve capability, speed, service reliability, ease of operation, and cost-of-ownership.

The highlights of the 3880 Die Bonder are its now-standard features:

- Standard Bi-Directional 8 Tool Turret: The 3880 Die Bonder includes the fastest and best bond head technology instead of it being optional, which equates to a 5% decrease in cost to the customer.

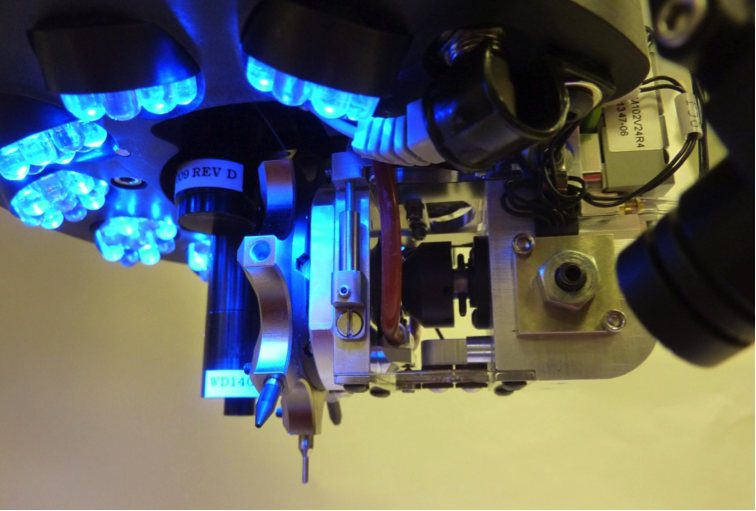

- "PURE Z" Technology: Prevents over-travel, slippage or floating of the bond head as it comes into the contact with the part. The 2 key components of "PURE Z" Technology are:

- Integrated Z-Leveling mechanism

- Integrated Touch Contact Sensor

- Tool Change Speed: Compared to the 3800 standard uni-directional model, the 3880 tool change speed has increased by 250% and is dramatically better than single tool die bonders on the market.

- Tool change time is critical for 2 reasons:

- Net throughput will increase for applications that require several tool changes per part.

- Time at temperature will be reduced, which is critical for eutectic applications.

- Tool change time is critical for 2 reasons:

Tool Change Speed Comparison

| Palomar 3880 | Palomar 3800 | Single Tool Die Bonder |

|

| Single Tool Change Speed |

0.25 seconds | 0.625 seconds | 3-6 seconds |

| Tool Position 1 to Tool Position 8 – Tool Change Speed | 0.25 seconds | 4.55 seconds | 3-6 seconds |

- Planar repeatability: dramatically improved by 400% (compared to the 3800 model). The new 3880 Die Bonder has a planar repeatability spec of 0.00361 degree, 3 sigma.

- This is very important for applications that have long parts. More specifically, planar repeatability is very important for optoelectronic die attach applications and AuSn laser die attach.

- Planar repeatability is calculated in 2 possible ways:

- Planar angle: 0.00361 degree

- Planar dZ = (0.0001/1.587)*L, where L is the length of the die and dZ is the change in parallel over the entire length of the die

- Force control and wider range of force capability: "Pure Z" Technology plus enhancements in local sensors, software, and the use of voice coil technology on the bond head enable the 3880 Die Bonder to have a combined ability of low force (5 grams) and high force (1000g) in the same bond head with more control, visibility, and easier set up.

With the above improvements, the new 3880 Die Bonder will provide users the ability to hit the best speed, accuracy, and capability performance specs on a wider range of applications. This equates to lower cost-of-ownership, higher value-add, and long term performance sustainability.

If you have a microelectronic or optoelectronic packaging and assembly requirement, we look forward to showing you the value the 3880 Die Bonder can realize for your business.

Download the 3880 Die Bonder Data Sheet for more information:

_____

Rich Hueners

Vice President of Sales & Marketing

Palomar Technologies, Inc.