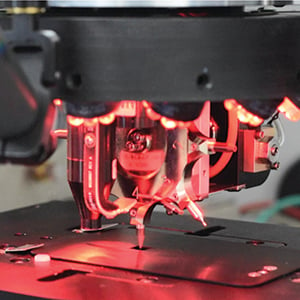

Eutectic die attach involves bonding a chip or die to a surface using a solder alloy. These particular solder alloys are used because of their unique property of having a eutectic melting point. Eutectic melting points are much lower than the melting points of the metals that make up the alloy. The challenges to eutectic attach are derived from the short amount of time the solder remains liquid and the general method to introduce the solder in the bonding process.

While the challenges have always been present and can be worked around without too much difficulty in non-automated environments, with the changing landscape of materials, some new issues arise while others grow in complexity. Chip design has become thinner and more fragile with changes in material, while also becoming smaller and denser [1]. This kind of design presents challenges in manipulating the die in general, but it also presents some difficulty in how to apply the right amount of force and control to develop proper wetting and bond formation. As an added concern, with the increasing density of chips, the importance placed on achieving good bonds with very low voids means that it becomes even more vital that the necessary amount of heat transfer required for the chips to function is provided. Finally, to tackle all of these challenges simultaneously and achieve consistent results in an automated environment, it becomes necessary to have control over each of these elements for successful mass production.

with the changing landscape of materials, some new issues arise while others grow in complexity. Chip design has become thinner and more fragile with changes in material, while also becoming smaller and denser [1]. This kind of design presents challenges in manipulating the die in general, but it also presents some difficulty in how to apply the right amount of force and control to develop proper wetting and bond formation. As an added concern, with the increasing density of chips, the importance placed on achieving good bonds with very low voids means that it becomes even more vital that the necessary amount of heat transfer required for the chips to function is provided. Finally, to tackle all of these challenges simultaneously and achieve consistent results in an automated environment, it becomes necessary to have control over each of these elements for successful mass production.

Read our full article in Chip Scale Review: https://www.chipscalereview.com/blog/Eutectic-die-attach:-a-highly-reliable-solution-for-advanced-materials-and-automation-challenges?

Download these resources for more information on eutectic die bonding:

| 3880 Die Bonder Brochure | 6500 Die Bonder Brochure |

|

|

----

Kyle Schaefer

Product Marketing Manager

Palomar Technologies, Inc.

Anders Schmidt

Applications Engineer II

Palomar Technologies, Inc.