Palomar Innovation Centers are experts in process development and work with customers in the areas of design for manufacture, process development and optimization. This case study documents an example of how Palomar engineers worked with the customer to maximize a high-mix process for high volume production.

One of the key challenges of a high mix production is being able to handle numerous form factors of parts and the ability to perform various process steps that apply to these types of packages. In this case study, the challenges of this high-mix process were:

- Dealing with an array of different product form factors, processes, and component types

- Maximizing machine utilization

- Quickly training the workforce to be effective in production

Figure 1 shows an example a typical high mix range of products needed to run through a single production line.

- Panelized PCBs

- TO Cans

- Ceramic RF Packages

- Flip Chip Bonding

- Singulated Silicon Die

- Discrete Component attach onto 8” Wafer

Figure 1. Images showing the various range of products in a high mix environment.

Figure 1. Images showing the various range of products in a high mix environment.

This challenge was met by utilizing the large work area and customizability of the work envelope of the Palomar 3880 die bonder to incorporate various technologies to meet all of these needs in a single machine configuration.

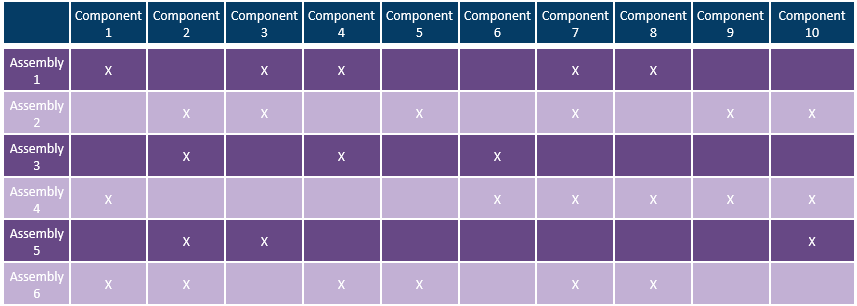

Another challenge with high mix productions is handling common components and processes across multiple programs and assemblies. As you can see in this matrix in Figure 2, each component is used in at least two assemblies. Managing and standardizing references, pick and place, dispense, and wire bond parameters for each component is essential for quality and process control in a high mix setting.

Figure 2. The common components across multiple assemblies in this case study.

Figure 2. The common components across multiple assemblies in this case study.

Managing the challenge of common components was primarily accomplished with the die bonder software. The software has the capability to transfer parts, dispense patterns, and parameters across programs to reduce unnecessary/redundant programming time and program to program variation – as well as minimize user-to-user variation in programming.

Identification schemes transfer from bonder to bonder as well – barcode, QR, Optical character recognition, manual, etc. This ensures that each component’s traceability scheme is maintained and consistent across the entire suite of packages it is being used in. The Palomar die bonders also have the ability to store images of each reference to create a quality record for each component that was picked and placed. This is particularly helpful when tracking down lot-based quality issues.

Maximizing Machine Utilization

A third challenge faced, due to the large number of different components and attachment methods, is the need for various epoxy application methods, custom pick tools, and “utility” stages. This included:

- 28 tools

- 6 different types of epoxy

- 4 different custom dispense tips

- 8 presentation stages

This can certainly present a challenge with process changeover – necessitating hardware changes for pick tools, stages, and epoxy dispense hardware – adding hours of machine downtime and potential setup variation between each run.

Several hardware solutions mitigated these challenges. The first of these is the introduction of a new tool dock that increased the total number of available pick tools beyond the eight locations in the tool turret. This solution eliminated the need for users to load and calibrate the appropriate tools during process changeovers, thus increasing bonder up-time.

Another hardware solution that helps to meet this challenge is a triple dispense bracket capability which can be outfitted with various dispense technologies; such as time pressure, auger, or jetting. Additionally, new and improved epoxy daub pots allow for quick changeover between epoxies, highly accurate epoxy depth setup, and ease of cleaning. The use of generic stages with customized tooling plates allows for numerous and highly varied form factors to be run without the need to add or remove any stages between processes.

Lastly, a new high force hardware improvement is available on the Palomar die attach systems. This gives the flexibility to run both traditional die attach processes that require lower forces, as well as those that require higher force such as flip-chip thermocompression, all on the same system. This new hardware option also allows for large/oversized pick tools for picking and placing much larger components that require tool sizes of 2-3 inches.

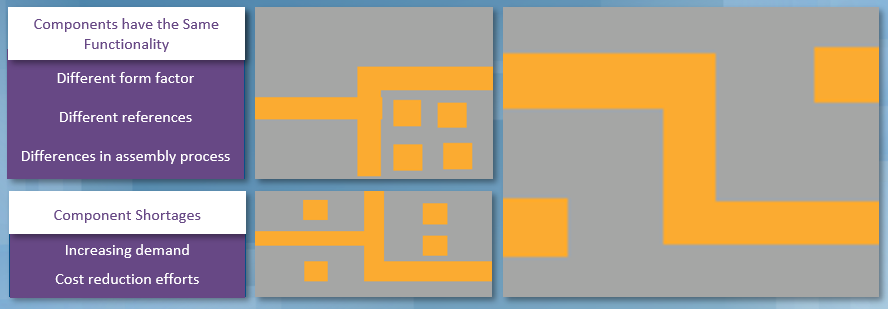

A fourth challenge for high mix production is that a particular part number that has the same performance characteristics may show up in various form factors and with different art/layout on the top surface. This becomes much more pronounced as global supply chains are strained. In Figure 3, an example of a part number that had three die layouts – each layout having the same performance characteristics, but with different lengths, widths, and bond pad locations is shown.

Figure 3. The difference between alternate parts with the same performance characteristics.

Figure 3. The difference between alternate parts with the same performance characteristics.

The challenge of these alternate parts was managed and handled through software capabilities which allow for the programs to identify and recognize different part geometries and wire bond pad locations for alternate parts within the assembly.

Once programmed, the bonder will look for the first part iteration, then if it fails to find that first iteration, will move down a chain of part iterations until the correct part layout is identified. The program then knows where each wire should be connected for the layout that it identified. This reduces the need for managing various revisions of a program to accommodate all component iterations. Doing this type of management for a handful of assemblies is painful, yet manageable. However, in this case, there were over 100 unique assemblies running through the same line. This can certainly lead to “line down” situations to accommodate these variations unless the equipment has this capability built in.

Quickly Training the Workforce to be Effective in Production

Manufacturers face many challenges regarding the workforce when bringing new equipment and processes on line at their facilities, whether they are new employees with a bachelors or a master degree, to operators or technicians. One of the main challenges faced with these employees that were completely new to the industry, but certainly had the aptitude, was getting them up to speed not only on the new equipment, but also the processes on this equipment, including the ancillary process steps necessary for successful production.

Another challenge that manufacturers regularly face regarding employees is turnover and how to manage that on complex niche equipment and processes. This can be mitigated with training on the equipment including general equipment training - basic operator and programming training.

Once the customer’s employees were familiar with the equipment and general operation, they shadowed staff within the Palomar Innovation Center who were doing the process development. This enabled new employees to see and learn best practices for programming and process development, as well as learn which checkpoints were needed for this process. At the end of process development within the Innovation Center, a small volume run was completed to enable maturing of the process.

Then, the programs were transferred to the equipment on the final productions site and small volume qualification runs were performed to prove the process. This allowed for the employees to be involved and gain hands-on experience which ultimately led to a high degree of competency and self-reliance.

During the process, the Palomar Innovation Center provided “design for manufacturing” advice and helped to automate the manufacturing of the products to achieve high yield and avoid unnecessary challenges in production.

These collaborative efforts delivered the following benefits:

- Increased production volumes by minimizing downtime between processes

- Reduced quality incidents through thorough employee bring up

- Perform rapid process development and transition into production

For more information about how to optimize a high-mix process for high-production, download our article: The Journey to Full-Scale Semiconductor Packaging Manufacturing.

For more resources, download these brochures: