Eutectic Bonding - Why is it Necessary?

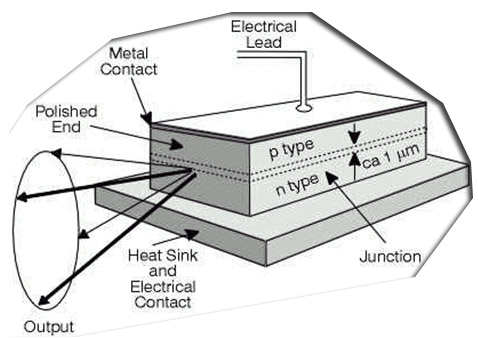

This Eutectic Bond consists of three key aspects:

- The Electrical Contact

- The Primary Heat Interface

- The Mechanical Support

Quick SCIENCE LESSON: The Law of Thermodymanics

- Energy can neither be created nor destroyed (you can't win!)

- Energy flows from a higher energy state to a lower energy state (hot or cold) **in the event of a tie, mother nature wins!

Eutectic Bonding - What Does It Prevent?

Catastrophic Optical Damage (COD): damage to the mirror coating reflects energy back in to the laser and overheats over time

Reduced Device Longevity: poor thermal interface will require higher current input for desired light output

"Noise" Feedback: adhesive bonds provide noisy feedback at data rates > 40 Gps

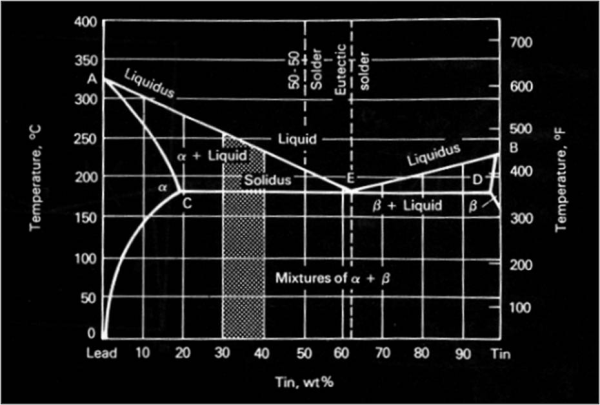

Eutectic definition: Easily Melted

*Point "E" is the mixture point where heating the solder results in pure solid to pure liquid transition

How to Join with Solder: 2 Things Needed

HEAT and WETTING: 1) Need sufficient heat to melt and reflow the solder and 2) Don't want excessive heat that will damage the components OR the surrounding components.

Wetting vs. Non-Wetting

Solder droplet contact angle "0" affects wetting.

It's important to keep in mind some of the process variables with eutectic bonding. Palomar Technologies' eutectic process can control the following:

- Temperature

- Time

- Force scrub

- Gas environment

Other variables, not controlled with Palomar's process:

- Die material

- Solder material

- Solder size

- Solder presentation method

- Substrate/bond pad material

- Cleaning methods

Learn more:

Download the "Automated Eutectic Die Attach" eBook: