With the creeping rise in the price of gold, many microelectronics manufacturing companies have been looking for alternatives to reduce the cost of ball bonding. Recently, the trend has been to look into the use copper wire. However, there are many drawbacks to using copper wire, including the short shelf life of pure copper wire, EFO must occur in a forming gas (N2 + 3H2) adding cost and infrastructure, and Palladium-coated copper wire also adds cost to the wire.

Silver (Ag) Alloyed Wire IMAPS held their annual “Topical Workshop & Tabletop Exhibition on Wire Bonding” in San Jose, CA last month where a presentation was delivered on Silver (Ag) alloyed wire as an alternative to copper or gold wire. Within the last few years, some wire manufacturers have created silver alloy bonding wire with their own specific recipes for the alloy. Alloying silver has been useful to eliminate the silver migration phenomenon. The price of silver alloy wire is somewhere between Pd-coated copper and gold. Silver alloy wire has similar wire bonding properties, such as a similar hardness to gold. A couple of purported useful applications are in LED manufacturing and solar panels.

IMAPS held their annual “Topical Workshop & Tabletop Exhibition on Wire Bonding” in San Jose, CA last month where a presentation was delivered on Silver (Ag) alloyed wire as an alternative to copper or gold wire. Within the last few years, some wire manufacturers have created silver alloy bonding wire with their own specific recipes for the alloy. Alloying silver has been useful to eliminate the silver migration phenomenon. The price of silver alloy wire is somewhere between Pd-coated copper and gold. Silver alloy wire has similar wire bonding properties, such as a similar hardness to gold. A couple of purported useful applications are in LED manufacturing and solar panels.

On the other hand, there are challenges in using silver alloy wire as well. With the alloys comes added electrical resistance, which is a negative for many applications. Also, silver alloy ball formation cannot be done in room atmosphere (it needs N2 only). There is also the drawback concerning the suitability of silver alloy wire to any given application; for example, it is probably not suitable for use in radio-frequency applications.

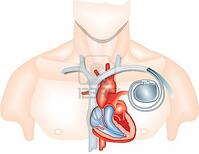

Platinum (Pt) Wire In recent years, the price of gold has approached the price of platinum, making Pt a contending option for wire bonding versus Au wire. The excellent biocompatibility of platinum, combined with its good stimulation and sensing properties, makes this precious metal a top choice for use in life-saving cardiovascular implants such as defibrillators and pacemaker electrodes.

In recent years, the price of gold has approached the price of platinum, making Pt a contending option for wire bonding versus Au wire. The excellent biocompatibility of platinum, combined with its good stimulation and sensing properties, makes this precious metal a top choice for use in life-saving cardiovascular implants such as defibrillators and pacemaker electrodes.

| Download the Assembly Services Data Sheet here |  |

Palomar Technologies Assembly Services offers a wide range of contract packaging solutions, including gold and platinum wire bonding processes. Also, the 8000 Wire Bonder is currently in use by implantable medical device manufacturers to acheive high-precision, high-reliability Pt wire bonding. Learn more: Platinum Wire Bonding Reliability and Biocompatibility for Implantable Medical Devices

In conclusion, with the rising cost of gold and the drawbacks of using copper wire in some instances, alternate materials such as Ag alloy wire and Pt wire are being researched and tested for certain applications. The 2013 IMAPS Wire Bonding Workshop was another successful event, highlighting many experts and new discoveries in the wire bonding industry.

----

David Rasmussen

Assembly Services General Manager

Palomar Technologies, Inc.