Throughout the history of electronics manufacturing, there have been distinct boundaries between those that assemble SMT components and those that assemble microelectronics. In today’s market, it is difficult to identify a U.S. source for low-volume prototype services that offers both disciplines.

SMT and microelectronics die and wire bond services are not usually found in one contract assembly location. In the past, organizations had to deal with two different companies to fulfill build requirements. For example, hybrids or chip on board (COB) integrate wire bonding directly on the board.

The applications, required processes, thermal considerations and particular board all must be considered in determining which procedures involve SMT and microelectronics assembly in addition to which order these processes should occur.

Although rare for equipment manufactures to offer contract assembly services, equipment manufacturers often are in the best position to understand and perform assembly processes. They know how to use their equipment, reconfigure it for many unique applications and have experienced engineers dedicated to fine-tuning customers’ processes and products on the equipment.Microelectronics assembly processes are applied for applications including advanced wire bonding, gold ball bumping, high-power LEDs, MEMS devices, microwave and RF components, optoelectronic packages, multichip

advanced wire bonding, gold ball bumping, high-power LEDs, MEMS devices, microwave and RF components, optoelectronic packages, multichip

For a designer and manufacturer of automated high-precision wire bonders and component placement systems, positioning the company to support the scalable production of complex microelectronic devices at its own facility can be a natural progression, as it was for Palomar Technologies. With proper planning, equipment manufacturers can take a product from design to volume-production at a lower cost, in a shorter time and with less risk than a company not specialized in these technologies trying to do the prototyping, manufacturing and test on its own.

Although these SMT and microelectronics assembly have been--traditionally--separate, more manufacturers are faced with both SMT and microelectronics build requests since many boards and assemblies are requiring mixed technologies.

SMT Working with Microelectronics Assembly Traditional microelectronics assemblies require a class 100,000 cleanroom for most operations with some of the sub-processes requiring class 10,000. Expertise is expected in process engineering, die attach, wire bonding, and custom deliverable parts. Most companies looking to outsource these processes want someone with 15-to-20 years of experience in building microelectronics parts.

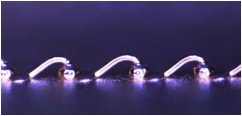

Traditional microelectronics assemblies require a class 100,000 cleanroom for most operations with some of the sub-processes requiring class 10,000. Expertise is expected in process engineering, die attach, wire bonding, and custom deliverable parts. Most companies looking to outsource these processes want someone with 15-to-20 years of experience in building microelectronics parts.

Taking into account and planning of SMT and microelectronics assembly simultaneously has many advantages. Simultaneous production planning enables process engineers to look at the total product rather than at one board or view it in isolation. Temperature plays a large part in determining the order of assembly; maximum temperature requirements for wire bonding can be different than for other components. Working together enables an evaluation of which part needs which processes and at what temperature profile so as not to destroy other elements of the component or adjacent wire bonds.

Case Study: Detector Manufacturer

A detector manufacturer was looking for a company to provide prototyping/low-volume sourcing and assembly services for a PWB panel that required multiple assemblies and depanelization to fit in a handheld monitor. The project entailed both surface mount and microelectronics assembly services, which rarely are offered together. A solution was available from an unexpected source: a manufacturer of automated precision wirebonding and die-attach equipment. Download the case study to learn more about the process solution.

SMT + Microelectronics Assembly: Why It Works

Palomar Technologies Assembly Services(TM) offers low-volume/high-mix prototype manufacturing services for companies in need of rapid design and assembly of precision micro-devices. Collaboration with an SMT-focused solutions creates a single source for SMT and microelectronics assembly.

Download the technical paper: Surface Mount Technology and Microelectronics in One

Download the technical paper: Surface Mount Technology and Microelectronics in One

----

Donald Beck

General Manager

Palomar Technologies Assembly Services