Carlsbad, CA – May 5, 2015 – Palomar Technologies, the world-leading provider of precision microelectronics and optoelectronic packaging systems, will be introducing the 9000 Wedge Bonder to Germany at the 2015 SMT Hybrid Packaging conference in Nuremberg, Germany on May 5-7. They will be showcasing the 9000 Wedge Bonder as well as their 8000i Wire Bonder at their booth located in hall 7A, booth 7A-521.

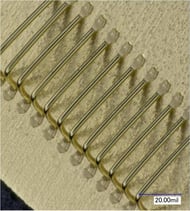

The 9000 Wedge Bonder is a high-speed fine wire wedge and ribbon bonder, offering control and flexibility. The 9000 features a large 12”x6” work area and the ability to easily change from a 45-60° wire feed range to 90° deep access. The quality control enabled by the 9000 is unparalleled, with real-time bond monitoring and process control software as well as a robust, low maintenance bond head. With the 9000 there is no need for an expensive bond head change, as the wire clamps are easily replaceable and adjustable.

There are seven strategic components to the 9000 Wedge Bonder that help customers achieve modern wedge bond requirements:

- Large work area

- Inline factory automation

- Advanced user control

- Bond data miner

- High-speed wire bonding

- Wire feed clamp versatility

- High-precision

Palomar Technologies pioneered the first automated fine wire wedge bonders in the 1980s and today carries the technological legacy into the industry’s most advanced fine wire wedge bonder on the market.

Operational Features for Control and Precision

The Intelligent Interactive Graphical Interface® (i2Gi®) is an advanced GUI software feature implemented on the 9000 Wedge Bonder, and is an exclusive Palomar Technologies technology. i2Gi offers the required management tools for modern wedge bonding, from part design and development, to process validation, and finally to intuitive operations control. i2Gi was designed for 9000 Wedge Bonder operating technicians to work smarter, faster and with more control.

The natural navigation flow and interactive live graphical display of i2Gi lets bonder program developers and operators experience real-time bonding and part quality validation. i2Gi technology supports advanced wedge bond control through command tools which work in concert to provide a dynamic and intuitive user experience.

Process Advantages

The 9000 Wedge Bonder addresses a wide range of fine wire wedge bond applications including disk drives, large complex hybrids, MCM power connections, ribbon bonding, low profile wire bonds, running stitch interconnects, and fine pitch devices. Some process advantages of the 9000 Wire Bonder include:

- Providing various loop form functions

- Highly regulated constant wire length

as well as loop height - Individual loop shapes

- Loop length range from

70um to 20mm.

The 9000 Wedge Bonder also incorporates Bond Data MinerTM which is an all-inclusive and centralized data management and analysis system. This is a powerful tool to improve yield and utilization.

Delivering What Programmers Desire

Modern wedge bond requirements demand an automated, large bonding area system with scalability to increase production capacity without limiting performance. In order to achieve best efficiency at lowest cost, programmers and operators need relevant and real-time production feedback from their equipment.

With the 9000 Wedge Bonder, lab managers are able to have peace of mind that their bonder is fully supported by a highly trained team of field service and process development consultants.

| 9000 Data Sheet | i2Gi Data Sheet |

|

|

###

Media Contact

Claudia Salerno

Marketing Communications Manager

Palomar Technologies, Inc.

csalerno@bonders.com | +1 760-931-3681