SST Vacuum Reflow Systems offers customers far more than just high performance vacuum/pressure soldering systems. When acquiring a system, customers should seriously consider taking advantage of the process consulting assistance that SST provides for the following reasons:

- So your system is in production in the shortest possible time.

- For immediate successful completion of a customer project.

- Reducing the overall cost of using externally designed and fabricated tooling, process profiles, and deciding how to optimize the soldering profile by trial and error (which could take months of time).

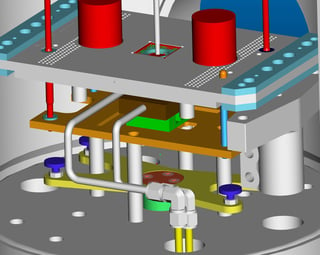

- SST has 50 years of experience developing and refining processes that create void-free, flux-free solder joints. Custom engineered tooling design with improvements learned over those years is combined with in house fabrication of tooling using specialized and custom machinery. Using only proprietary semiconductor grade graphite, our craftsmen create tooling to contain the parts

- SST’s fully equipped application lab allows our process engineers to create, develop, test, and refine optimized profiles for customers, allowing them to quickly get to production level output.

- Using our customers’ actual parts, SST engineers can demonstrate the success of the soldering process. They can verify low voiding in die attach applications by X-ray or CSAM tests, or verify lid sealing applications through fine helium leak testing and gross bubble testing as per Mil Spec 883.

- SST’s Process Development Team has special expertise in the areas of mechanical design, metallurgy, thermodynamics and high vacuum technology—all relating directly to microelectronic package assembly. They are a team of experienced design and process engineers with the know-how to overcome process challenges and develop solutions that work.

A typical process development project follows a series of defined steps to ensure understanding of outcomes, activities, responsibility and costs. To take advantage of the combined knowledge of SST’s process engineers, designers and fabricators, please contact your local SST representative.

A typical process development project follows a series of defined steps to ensure understanding of outcomes, activities, responsibility and costs. To take advantage of the combined knowledge of SST’s process engineers, designers and fabricators, please contact your local SST representative.

Download these resources for more information:

| Process Development | Graphite Machining | Void-Free Die Soldering |

---

Pierino Zappella

Process Engineer

SST Vacuum Reflow Systems