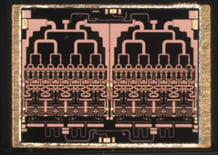

Gold-Tin AuSn Die Attach Gold-Tin AuSn Die Attach |

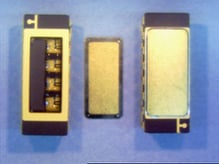

Gold-Tin AuSn lid seal with a combo lid attached preform Gold-Tin AuSn lid seal with a combo lid attached preform |

Material Properties:

- Lead free

- Very high tensile 40,000 PSI

- Very high shear strength 40,000 PSI

- High thermal conductivity 0.57 W/cmC @ 85°C

- Low thermal coefficient of expansion 16 ppm/C at 20°C

- Good thermal fatigue properties

- Good resistance to alkaline corrosion

- Excellent solder to use when soldering to gold

- Available in thicknesses from as thin as 0.5 mil (0.0005 inch) up to several mils (as needed)

- Available in custom size dimensions, can be punched out in solid flat preform for die attach application or in ring format (square or rectangular) with open center for lid seal application

(Reference: Indium Corp. Solder Alloy Directory)

Process Advantages/Disadvantages:

- Gold-tin does not require any flux or chemical acid etch treatment to remove surface oxides as required by other common indium, lead, or tin-based solder alloys

- Flows well when molten on properly gold-plated surfaces

- Can be tack welded onto lids so that lids can be obtained with pre-attached preforms called combo lids

- Long history of successful die attach and hermetic lid sealing

- Does not scavenge gold as much as conventional tin-rich solders which scavenge gold very aggressively

- Higher cost than common lead and tin-based solder alloys due to high gold content

- Brittle material difficult to trim or cut by hand

- Shiny smooth silver color upon reflow for good cosmetic appearance

- Melting point temperature increases after initial reflow, as gold is consumed from the gold plated mating surfaces to increase the gold content. This is an advantage and dis-advantage (refer to Figure 1: Gold-Tin Phase Diagram)

- Disadvantage: Cannot do subsequent reflow at 278°C must go higher in temperature.

- Advantage: Gold-tin can be used for die attach and then subsequent lid seal in the same package without secondary reflow of die attach solder joint.

*At 18% tin content the melting point increases to 350°C

*At 16% tin content the melting point increases to 400°C

Reference: Indium Corp.

For more information, visit the SST Vacuum Reflow Systems website or check out these resources:

| Void-Free Die Soldering Whitepaper  |

Soldering Gold Surfaces Using Gold-Tin Solder Material Whitepaper  |

----

Zap (Pierino) Zappella

Process Development Engineer

SST Vacuum Reflow Systems