The QuikCool rate profile achieves lower void concentration versus normal rate profile in AuSn solder alloys.

AuSn is the “best” alloy to use due to its strong mechanical properties, fluxless and chemical-free etchant treatment compared to other indium, lead, and tin-based alloys. The QuikCool process was applied to AuSn eutectic-based alloys. The critical point in AuSn alloy is 280°C, the point at which both the solid and liquidus phases exist. Here, preform pieces of 1 mil AuSn (80wt% Au and 20wt% Sn) were used to join direct bonded substrates (DBCs) metallized with Si die attach. Thus, in order to achieve low void concentration <1% and reduction in cycle times in solder alloys, the QuikCool system feature is an excellent alternative.

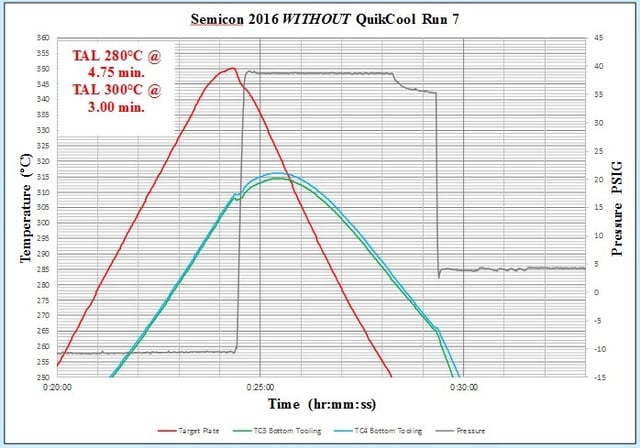

We developed a process approach to a QuikCool system time above liquidus (TAL-critical point). See the graphs below; we compared two different profiles: normal rate profile vs. QuikCool with both profiles using ramp of 4.5 minutes to achieve void concentration <1%. The TAL of the normal rate profile was seen to have ~4.75 minutes at 280°C, whereas at 300°C was ~3.00 minutes.

a)

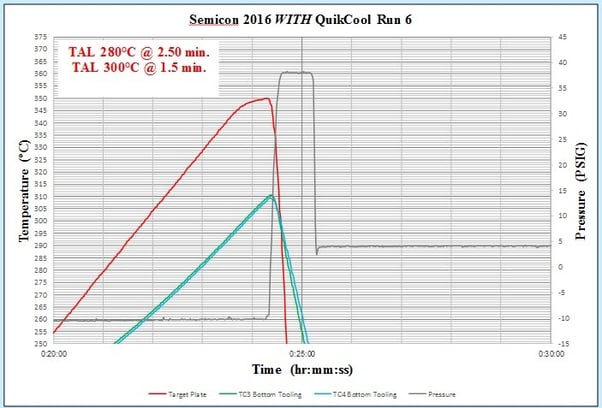

b)

b)

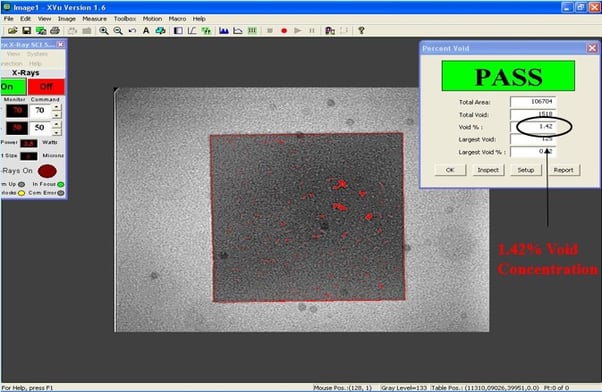

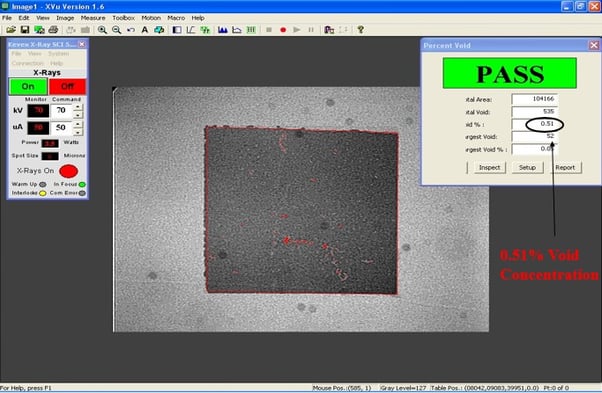

The TAL with QuikCool rate profile at 280°C was ~2.50 minutes whereas at 300°C was ~1.50 minutes. The void concentration of the normal rate profile was ~0.91% increase in void concentration as compared to the QuikCool rate profile. Void concentrations are shown below in figures C and D, respectively. A decrease in void concentration was achieved with the QuikCool rate profile as compared to the normal rate profile.

c)

d)

Download these resources for more information:

| Model 5100 | QuikCool | Process Development |

---

Adrienne D. Williams, Ph.D.

Process Engineer

SST International