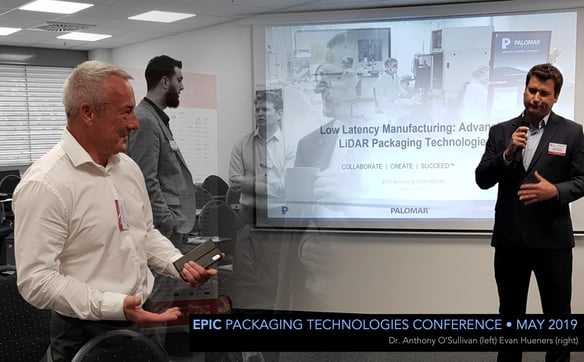

Palomar Technologies recently sent two delegates to EPIC’s Packaging Conference, hosted by ASM Amicra, in Regensburg, Germany. The annual event showcases advances in packaging technologies, as well as new approaches furthering a wide range of innovation solutions. Palomar’s Product Marketing Manager, Evan Hueners, presented aspects of Palomar’s experience in supporting EEL and VCSEL facilitated LiDAR devices. He stated that sustainable advances in manufacturing efficiencies are as central to the future of commercial design and production, as are technical improvements, better physical specifications, or even tighter tolerances. This vital dynamic was succinctly summarized in his presentation, “LiDAR Packaging and Low Latency Manufacturing Solutions.”

Dr. Anthony O’Sullivan, Palomar’s Strategic Market Analyst also attended the event. “The message was well-received because it complemented the fuller dynamic of the conference. It has been said that ‘high-tech sells high-tech’, but increasingly we are in an era where high-tech makes high-tech. This is not just about SMART technologies, robotics, improved manufacturing infrastructures, or even utilizing Industry 4.0 and IoT, but from the perspective of a holistic oriented approach. On first hearing, ‘low latency manufacturing’ it sounds quite ethereal, but the concept is actually about a vital, highly practical upgrade in commercial engagement; a business ethos committed to unlock efficiency through the collaborative and holistic adoption of innovation, invention and adaptation. This occurs on the manufacturing floor, certainly, but also looking upstream and downstream from this point. In short, an entire commercial culture making a vast range of responses, across as wide an area of production, efficiently and dependably, in as short a time as possible.”

“As to Palomar’s particular model of low latency manufacturing,” Evan explains, “core elements consist of continuous customer engagement using a holistic and collaborative process approach. This collaborative approach combines elements of package design, process optimization and metrology, all crucial for successful new product introductions (NPI) which are continually refined with the customer over the entire product lifecycle. Optimum engagement between Palomar and the customers at this juncture, therefore, remains essential. Thus, a deep understanding of the winning principals that got you ahead in the first place, are a good place to start when initiating further improvements, such as a cost reduction effort on a product. The two-way learning process between the OEM and customer, already vital, must be increasingly responsive, adaptable and agile as we move towards a new decade.”

Fundamental to the early phases of product development, Palomar is adapting the principles and extending the process across a lifetime of the product, through continuous revisions and improvements with customers. One example is our implementation of generic test vehicles, covering many variants, numerous functions and several device types, further improving device manufacturability and cost performance, yet all without sacrificing specificity where needed. Add to this a robust and ever-refined methodology capable of evaluating both the assembly metrics (e.g., pull, shear tests) and product metrics (e.g.,temperature, coupling, power) means that new levels of “essential” are road mapped on the path to a successful product launch.

Finally, it is no surprise that while Palomar is proud of its history originating in the Hughes Aircraft Corporation, and indeed its evolution and growth since becoming independently owned, our roots extend in the future. Palomar’s practice of low latency, collaborative manufacturing reaches well beyond today’s horizons. This is indicative of an entire workforce geared to ensure that the solutions invested into by our customers are technically relevant—and commercially attuned—but also anticipate the needs of the ecosystem, three, five years from now, and even beyond.

Palomar Addresses Packaging Conference

Palomar Addresses Packaging Conference

To learn more, download our data sheets:

| Palomar Technologies - Innovation Center Brochure | Palomar Technologies - 6532HP Die Bonder Data Sheet |

|

|