SST Vacuum Reflow Systems recently introduced an upgrade for graphite tooling. Over time, the thermocouple hole on the side of the boat begins to wear out, sometimes causing inaccurate thermal readouts or, even worse, causing the thermocouple to come out of the boat. Eventually the boat might need to be replaced, due to the damage of the thermocouple hole.

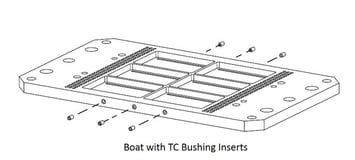

One of the improvements that SST offers to the boat for the 3130 systems, in order to increase its life, are additional options to TC holes. These options mitigate premature failures by repeated placement of the TC into the boat.

To eliminate this problem, SST is offering several solutions:

1. Special Metal Bushing:

This bushing is press-fit into thermocouple  hole. Molybdenum is a much harder material than graphite and as such, prevents the damage to the graphite boat during the thermocouple insertions. This option is available to all of the new tooling designs and the existing customer tooling boats can be upgraded, depending on its condition.

hole. Molybdenum is a much harder material than graphite and as such, prevents the damage to the graphite boat during the thermocouple insertions. This option is available to all of the new tooling designs and the existing customer tooling boats can be upgraded, depending on its condition.

2. Deeper Thermocouple hole:

SST can modify the existing boat (please consult with SST), to make the thermocouple hole(s) deeper, to assure a more secure contact between the thermocouple wire and the graphite boat.

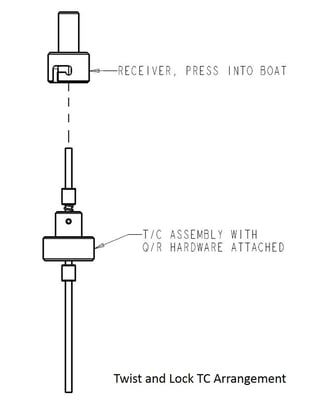

3. Twist-Lock Type:

The Twist-Lock connector is press-fit into the thermocouple hole of the graphite boat. The mating connector needs to be crimped to the thermocouple wire. This option assures a secure connection of the thermocouple wire to the graphite boat after many thermocouple insertions.

Download these resources for more information:

| Graphite Machining Datasheet | Model 3130 Datasheet | Process Development Data Sheet |

---

Alex Voronel

Regional Sales Manager

SST Vacuum Reflow Systems

Contact Us