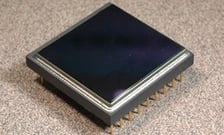

Microelectronic Mechanical Systems, or MEMS, technology is everywhere we look. The biotech, medical device, communications, and inertial sensing industries are increasingly using MEMS devices as miniaturization allows new synergies. Micro-displays, ink jet print heads, IR detectors, blood pressure sensors, and accelerometers are a few of the MEMS devices being used today, and it is inevitable that new applications will emerge. Some applications require MEMS devices to be packaged in a high vacuum environment. This means that the package is sealed under vacuum level below 10-06 torr.

A certain level of packaging protection is required for all MEMS devices; however, IR Microbolometers, Accelerometers, Gyroscopes, Atomic Clocks and RF MEMS require an internal package vacuum or controlled atmosphere to prevent degradation over the life of the device.

The complexity of high vacuum MEMS sealing falls into a few major categories:

- Operate a high vacuum furnace that is capable of:

- creating a high vacuum environment of 10-06 torr or lower

- creating a precisely controlled gas pressure

- applying controlled heat to the components

- activating the getter

- isolating heat from some components

- applying sealing force to package and lid

- operating automatic closed-loop controls

- providing reasonable production rates

- monitoring and logging all critical process data

- Material selection to ensure the long term reliability of the device:

- selection of the proper material for the package

- selection of suitable solder alloy for lid sealing

- selection of suitable getter material

- selection of low outgassing die attach compound

- Design and fabrication of the specialized tooling required to successfully create the MEMS package.

- Process knowledge and profile development to ensure the system is tested, proven, and programmed to achieve the desired outcome.

Since 1978, SST Vacuum Reflow Systems has developed and implemented the unique and complex mix of vacuum/pressure systems, materials expertise, programming and process profiles to achieve successful MEMS package creation. As a market leader in high vacuum MEMS sealing technology and the sealing process knowledge, our team will consult with you to assess, develop and implement the total solution you need to achieve your desired outcome.

To learn more, please contact us about your high vacuum MEMS sealing application requirements.

Download these resources for more information on SST Vacuum Reflow Systems:

| High Vacuum MEMS Packaging paper | 3150 High Vacuum Furnace Data Sheet | 5100 Vacuum/Pressure Furnace Data Sheet |

|

|

|

----

Alex Voronel

Director of Global Sales

SST Vacuum Reflow Systems