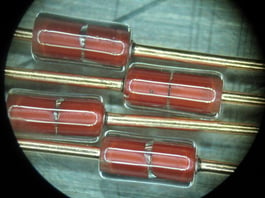

Glass to metal sealing technology has been around for decades and is still an important technology for many microelectronics products. Glass to metal sealing is used on devices ranging from glass diodes to hermetic electrical feedthroughs for vacuum packages. Ultimately glass to metal sealing is used to create a hermetic seal between two environments while allowing an electrical conductance path. The subsequent seal can withstand higher environmental and operational temperature than many other sealing technologies. To ensure “sealability” (which means that the thermal contractions of the two sealing components match each other below the transformation temperature of the glass), often glasses of special composition are required.

There are two main types of glass to metal seals:

- Matched Glass-to-Metal Seals

Matched glass to metal seal requires matched thermal coefficient of expansion of glass and metal. Coefficient of expansion of materials must be within 10% to prevent cracking. The strength of a matched seal comes primarily from a chemical bond between the glass and the oxide on

the metal parts. Metals must be oxidized for proper seals. Matched seals are most often made with Kovar housings

and pins, and borosilicate glass. Typical metals used are Kovar, Tungsten, and Molybdenum.

- Compression Glass-to-Metal Seals

Compression glass to metal seals do not require the oxidation layer as above matched glass sealing. Glass to metal compression seals are made with a housing material and a metallic inner pin. Coefficient of thermal expansion of the housing metal isconsiderably higher than the coefficient of thermal expansion of the glass and metallic inner conductor. Upon solidification of the seal during the manufacturing process, the housing will contract around the glass, applying a desirable compression stress on the glass bead, thus creating a hermetic seal. Typical compression sealing glasses are for steels and Ni-Fe-Co alloy metals.

References:

Schott Technical Glasses Physical and Technical Properties: Chapter 9: Glasses for Joining: pages 44 thru 56: see website below:

http://www.schott.com/epackaging/english/download/schott-brochure-technical-glasses_english.pdf

Download these resources for more information:

| Glass to Metal Sealing eBook |

3130 Data Sheet | Process Development Data Sheet |

----

Alex Voronel

Regional Sales Manager

SST Vacuum Reflow Systems