Applications requiring ultra-high-placement accuracies of 1μm to 3μm are resurfacing in several optoelectronic applications such as Arrayed Laser Print Head assemblies, P-Side Down Laser Attachment applications, and Multi-Channel Optical Communication products.

Palomar Technologies' lead scientists/engineers (Daniel D. Evans, Jr. and Zeger Bok) have developed a technical overview of the technologies, placement accuracies and attachment methods of two cases —Micron Level Placement Accuracy Case Studies for Optoelectronic Products."

Case 1: Multi-channel Communication Products (VCSELs)

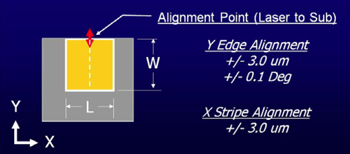

P-Side Down Laser Alignment to Substrate

P-Side Down Laser Alignment to Substrate

Requirements

Case 2: Wafer Scale – Eutectic Die to Wafer P-Side Down Laser Attachment

Generic Example Pulsed Heat Tool Profile

Generic Example Pulsed Heat Tool Profile

With placement accuracies for surface mount machines typically around 40μm, 10μm for die attach machines, and 1μm for ultra high accuracy placement machines, the whitepaper covers the differences in measurement, material, and process controls that are required to successfully achieve ultra high placement accuracies of 3μm.

Download "Micron Level Placement Accuracy Case Studies for Optoelectronic Products" to learn more now!

----

Jessica Sylvester

Marketing Communications

Palomar Technologies