For today's MEMS manufacturer, low volume and high complexity are no longer subject to only manual packaging processes. Automation is here, alive and working everyday throughout the world. Many MEMS device providers have configured automation into the design of their components. What we see today is that full-automation is not necessarily a requirement in MEMS production; but configuring the MEMS component design for automation is certainly worth its weight in gold as it reduces costs overall and positions a device manufacturer to handle the increasing demand of MEMS devices.

Designing MEMS devices for automation means ensuring they possess the precise physical features and tight manufacturing tolerances needed for an automated assembly process. Generally the machine (automated die bonder and component placement system) can place parts only to the accuracy allowed by the quality of the components its placing. For example, in the telecommunications industry where opitical MEMS devices are used in switching arrays, the MEMS must be placed with a high degree of accuracy, on the order of 1.5 to 2 microns in the X, Y and Z axes, and 0.2 milliradians in Theta axis. This and other similar applications require the components to be of the highest quality, hence the need for excellent component design.

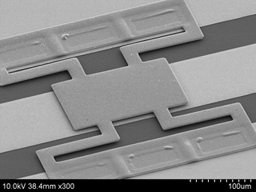

Physical features, such as metallization traces or fiducials, are used by the automated die bonder and component placement system's automated vision system to recognize the component's location and orientation. Oftentimes the required placement accuracy of a MEMS device is with respect to its microstructure. Therefore, MEMS manufacturers should ensure that the fiducials or metallization patterns are benchmarked to that structure. It should be noted that if the variance between the fiducial and the structure is greater than the acceptable placement accuracy, the required accuracy will never be met.

It is worth stating again that good MEMS design with an eye towards automated process production is ideal when looking to improve profit margins.