When we think of microelectronics manufacturing, we usually think about manual equipment, semi-automatic equipment, and fully automatic systems. However, there are levels of automation that we don’t always consider, especially when it comes to material handling. This blog will focus on what we call “fully automatic solutions”, but some of the concepts work similarly for all three levels of manufacturing equipment.

Manual Load and Unload

An entry level of material handling for automated microelectronics manufacturing is called manual load and unload. This is where an operator physically loads packages or panels into the system and manually starts the build process. For automated die attach, for example, this includes loading waffle or gel packs, film frames of expanded (diced) wafers, tape feeders, JEDEC trays, etc. along with the packages/panels that are to be populated. This takes some time and regardless of automation level, some of this is inevitable. The image below shows a manual load/unload scenario.

In terms of the die attach process, if traceability functions are needed, these still need to be manually entered (typed) or manually bar code read into the die attach system with a handheld reader.

Island of Automation

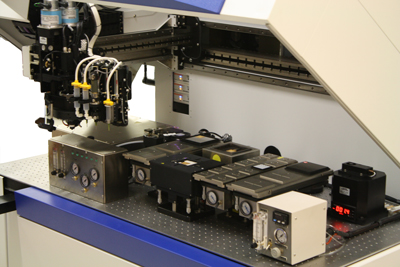

A fully automatic level would index, via edge belt or hitch feed, packages with material handling systems with custom tooling. Boats/panels/trays are moved into the working envelope from automated magazine loaders and accumulators. These systems integrate with each other typically through a simple two-wire communications link called SMEMA (V1.2), a surface mount specification. We call this configuration a “small island” of complete automation. The image below shows a similar configuration with magazine to magazine automation with an in-line material handling system.

With these three levels of automation comes a variety of benefits in terms of throughput and yields, but also with different cost structures. Material handling automation is not simple, and can be somewhat expensive. Weighed against yielded throughput, however, the differences all come down to a return on investment.

In-line Assembly Systems

The final level of automation is what we call a fully integrated in-line automatic microelectronic assembly line. It can include fluid dispensers prior to die attach. Each cell feeds automatically into the next. Once fluids are dispensed, automatic die attach occurs, and the product is fed into in-line convection curing ovens. These ovens can feed into in-line plasma cleaning systems, which feed into automatic wire bonders. In some cases, conformal coatings are applied next and cured; other times a lid is attached. In-line inspection stations can be placed at critical points.

Packages/panels start in boats which are fed from input magazine handlers. Assembly is performed as described above, and the finished parts are accumulated in output magazine handlers. This is the highest yielding, highest throughput scenario possible. With enough prior planning, these lines can be made with flexibility in mind to allow for some variation in package types. Only a few operators are needed to keep the entire (sometimes 70-100 feet long) line in constant 100% fully automatic operation. The image below is one of many examples of a fully turnkey, in-line automatic assembly solution.

The best news is that a program can start with a simple manual load/unload scenario and be field upgraded to a small island or fully turnkey in-line automatic microelectronic assembly line. A company can upgrade to the various levels of automation needs as packaging challenges expand and grow.

Learn more about microelectronics assembly solutions:

----

Bradley K. Benton

Western Regional Sales Manager

Palomar Technologies, Inc.