O – Optics

The purpose of an optical component is to manipulate light. Typically, when we think of LED optics, what comes to mind is a plastic lens of some sort used over the LED itself to focus or disperse the light. However, the LED itself has a protective casing called the primary optic. The primary optic serves two purposes: to protect and to shape the light output of the diode. The secondary optic are separate components that are usually made from optical-grade acrylic or polycarbonate mounted over the primary to help further shape the beam of light. The purpose of the secondary optic is to increase the relative luminous intensity.

disperse the light. However, the LED itself has a protective casing called the primary optic. The primary optic serves two purposes: to protect and to shape the light output of the diode. The secondary optic are separate components that are usually made from optical-grade acrylic or polycarbonate mounted over the primary to help further shape the beam of light. The purpose of the secondary optic is to increase the relative luminous intensity.

Optical components for LEDs play an all more important role in deciding the success of a light fixture. It is a real challenge for every fixture designer to be able to specify the optical components in a correct way, to enhance the properties of the fixture, while keeping the costs down. Putting together a functioning LED lighting solution always includes the specification of the optical performance of the product. As with many emerging technologies, LED technology being no exception, it may be very challenging to specify and choose the best components to fulfill the requirements set.

According to Osram, “In terms of durability and toughness, high quality light emitting diodes are superior to all other forms of lighting technology. LEDs manufactured by Opto Semiconductors (OS) operate in excess of 50,000 hours, meaning that light is more or less maintenance-free for the complete service life of a vehicle. This is one of the reasons why LED in car lighting is already the standard. More than 30 years ago in the initial stages of the technology, LEDs merely replaced very small incandescent lamps in car cockpits. Indicators in the tail section as well as tail lamps and brake lights were equipped with LED around 10 years ago, and daytime running lights later.”

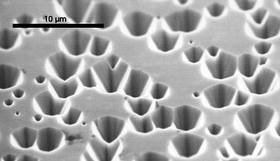

P – Pits

Common defects found after deposition of the epitaxial layer include micro-pits, micro-cracks, hexagonal bumps, crescents, circles, showerhead droplets and localized surface roughness. Pits often appear during the MOCVD process, correlated with the temperature gradients that result as the wafer bows from center to edge. Large pits can short the p-n junction, causing device failure. Sub-micron pits are even more insidious, allowing the device to pass electrical test initially but resulting in a reliability issue after device burn-in.

The sapphire substrate itself may contain a host of defect types, including crystalline pits that originate in the sapphire boule and are exposed during slicing and polishing.

Solid State Technology Journal: “The gleam of well-polished sapphire”, http://electroiq.com/blog/2013/01/the-gleam-of-well-polished-sapphire/.

“All Facts for Choosing LED Optics Correctly”, http://ledil.fi/sites/default/files/Documents/Technical/Articles/Article_1.pdf.

“Seeing the light: LED optics explained”, http://reefbuilders.com/2010/01/27/led-optics-explained/.

Photo credit:

http://reefbuilders.com/files/2010/01/led-optic-focusing-lens-1.jpg.

http://www.photonics.com/images/spectra/LED/2007/February/LEDPit_Fig1b_G1672sem004_1c.jpg.

----

Janine Hueners

Marketing Specialist

Palomar Technologies, Inc.