To live today without the assisitance and support of microelectronic-controlled devices is borderline unthinkable—unless you are romantic enough to live a life like in the dark ages. But, honestly, how long would you like it or even survive…?

It's hard to tell which is happening faster: the continuous trend that as microelectronic devices shrink, the more complex they become? Or the diminishing time between releases of the next generation of product?

Always a good visual example: The evolution of cell phone designs—no further explanation necessary! Here is the 1985 Siemens C1 Mobil Phone compared to the 2012 Apple iPhone S4.

But how do equipment manufacturers contribute to and support building such extremely small circuits, where packaging details can be recognized by using a high-magnification microscope?

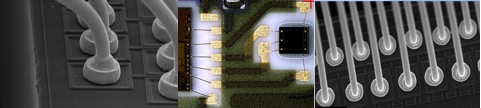

Microcircuits today also consist of one or more microchips/ICs (also called die) for its control. These die need to be connected to all other components of the circuit in order to make the device work as a whole. One commonly used interconnection method is ball bonding process technology (pictures below). Automatic ball bonders today can use Au wires from .7 – 2 Mil (18 - 50µm).

However, in order to be able to precisely hit the small bond pads of a die (≤100µm), device packaging requires a highly controlled, highly accurate wire bonding process. One basic requirement is the generation of a repeatable size of a “Free-Air Ball” (FAB): the start of any ball bonding sequence.

Palomar Technologies' 8000 Wire Bonder is equipped with a unique patented Deep Access Dual Axis Bond Head™. In addition to the linear Z-movement (Zl) for deep access applications, its tilting transducer (Zr) guarantees the precise tail length generation which is necessary to form consistent, repeatable ball bumps.

The following sketches show a comparison of Palomar Technologies' Free Air Ball generating features and obvious advantages to conventional ball bonders:

Typical bonding errors—such as the Golf Clubbing Effect, which can occur during electronic flame off action—are eliminated by using a fast Servo Motor. This motor drives the EFO actuator and precisely swings in the electrode right below the “tail” in the capillary to melt the wire and forms the ball as shown in the next sketch.

All unique hardware features in combination with a set of software parameters allows the operator to program any Free Air Ball Size within ±2µm, 3-sigma. Free Air Ball sizes can be created as small as 1.5x the wire diameter.

----

Josef Schmidl

Managing Director, Palomar Technologies GmbH

Palomar Technologies