Strategies in Light 2012 brought out the "who’s who" in Solid-State Lighting (SSL) technologies and capabilities. Palomar Technologies exhibited among the 5000+ attendees (almost double the attendees of 2011) at the 13th annual Strategies in Light conference, held in the heart of Silicon Valley at the Santa Clara Convention, February 7-9. Many attendees were just beginning to enter the market place and seeking answers to available materials, assembly process methodologies and challenges including cost reduction, power supply and heat removal.

With the applications for Light Emitting Diodes (LEDs) and High-Brightness (HB) LEDs expanding from the basic light blub—into automotive lighting, street signage and lighting to backlighting, medical and more—tighter performance and reliability in SSL are in high demand. Yet, another large hurdle surrounding SSL is the need to reduce the cost of LED manufacturing. As Greentech media recently reported, “it is the worst and best times for solid-state lighting (SSL): the market prognosis has never been worse and LEDs have never been better."

As the 3-day show progressed, the message was clear: there are many new players trying to break into a market that is quickly approaching peak saturation. Concerns on “over supply” rapidly surpassing “demand” didn’t dim the bright new hopefuls, but many attendees were wondering if the same thing happen to SSL as it did to solar. Moreover, with the U.S. Department of Energy Solid State Lighting Roadmap calling for an 85% reduction in final packaged LED cost in the next five years, it is truly too early to tell how many lights will go out for these new hopefuls.

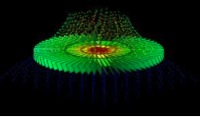

One thing is clear, in order to improve cost and performance, it is important to look at all aspects of the manufacturing and apply lean manufacturing principles.  Direct chip attach (DCA) is one method used to eliminate the need for wire bonding and help to increase throughput. By pre-deposited Au/Sn on the bottom LEDs for the electrical connection to the board, this allows multiple LEDs to be aligned on a board within an array pattern and reflowed at the same time. Large arrays of HB LEDs can be successfully packaging through DCA by utilizing a high-accuracy eutectic die bonder in combination with a Pulsed Heat System (PHS).

Direct chip attach (DCA) is one method used to eliminate the need for wire bonding and help to increase throughput. By pre-deposited Au/Sn on the bottom LEDs for the electrical connection to the board, this allows multiple LEDs to be aligned on a board within an array pattern and reflowed at the same time. Large arrays of HB LEDs can be successfully packaging through DCA by utilizing a high-accuracy eutectic die bonder in combination with a Pulsed Heat System (PHS).

Other discussions on HB LED performance in relation to heat were hot topics at Strategies in Light. Unfortunately, as HB LEDs  continue to burn bright, their phosphorus coatings do begin to degrade over time affecting the luminaries long-term performance. Many companies use metal-core boards in combination with heat spreader or cooling fans to reduce the heating affects. Depending on the application, various heat removal methods can be costly. Could there be a better way to remove the heat and still maintain performance without the expense? I encourage you to add your comments below!

continue to burn bright, their phosphorus coatings do begin to degrade over time affecting the luminaries long-term performance. Many companies use metal-core boards in combination with heat spreader or cooling fans to reduce the heating affects. Depending on the application, various heat removal methods can be costly. Could there be a better way to remove the heat and still maintain performance without the expense? I encourage you to add your comments below!

Palomar Technologies will have a tabletop display at the MEPTEC “Heat is On” conference on March 19th at the Doubletree Hotel in San Jose. We hope to see you there.

----

Julie Adams

Director of WW Sales, Assembly Services

Palomar Technologies