Arrayed laser print heads, arrayed ink jet print heads, P-side-down laser and multi-channel optical communication products all require ultra-high placement accuracies of 1um to 5um.

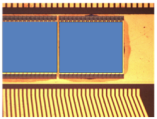

Arrayed print head technology—laser or ink jet—utilizes arrays of lasers or ink jets on individual die. The lithography processes used to create the arrays on each die are more than adequate to produce high-quality images. Conceptually, a single long die would allow a single-pass printing on the print medium. However, there is a practical limit to the length and width of die without affecting yield and handling damage.

Arrayed print head technology—laser or ink jet—utilizes arrays of lasers or ink jets on individual die. The lithography processes used to create the arrays on each die are more than adequate to produce high-quality images. Conceptually, a single long die would allow a single-pass printing on the print medium. However, there is a practical limit to the length and width of die without affecting yield and handling damage.

Mixing monotone and color printing requires that multiple rows or columns of print pixels be precisely aligned with respect to each other. Although some correction can be accomplished in electronics by modifying the print timing of each pixel, pixels must be aligned within a few microns for high-quality printed images. Print heads typically use high aspect ratio die to maximize the number of pixels per die and to minimize the amount of silicon.

Learn More.

Download "Micron-Level Placement Accuracy For High Aspect Ratio Die in Printing Products" for a deeper dive in to printhead application packaging, including:

- Production equipment and process features for practical automation of micron level placement accuracy

- Critical adhesive control

- Fine line dispensing prior to die bonding

- Material feeding

- Identification tracking

- Vibration isolation

Micron-level placement accuracy of 1um to 5um is presented in this paper for large die with lengths greater than 30mm and high aspect ratios of nearly 10:1. Both “side by side” and “end to end” die arrays are presented along with their corresponding results.

Micron-level placement accuracy of 1um to 5um is presented in this paper for large die with lengths greater than 30mm and high aspect ratios of nearly 10:1. Both “side by side” and “end to end” die arrays are presented along with their corresponding results.

---

Daniel Evans

Senior Scientist / Applications Manager

Palomar Technologies