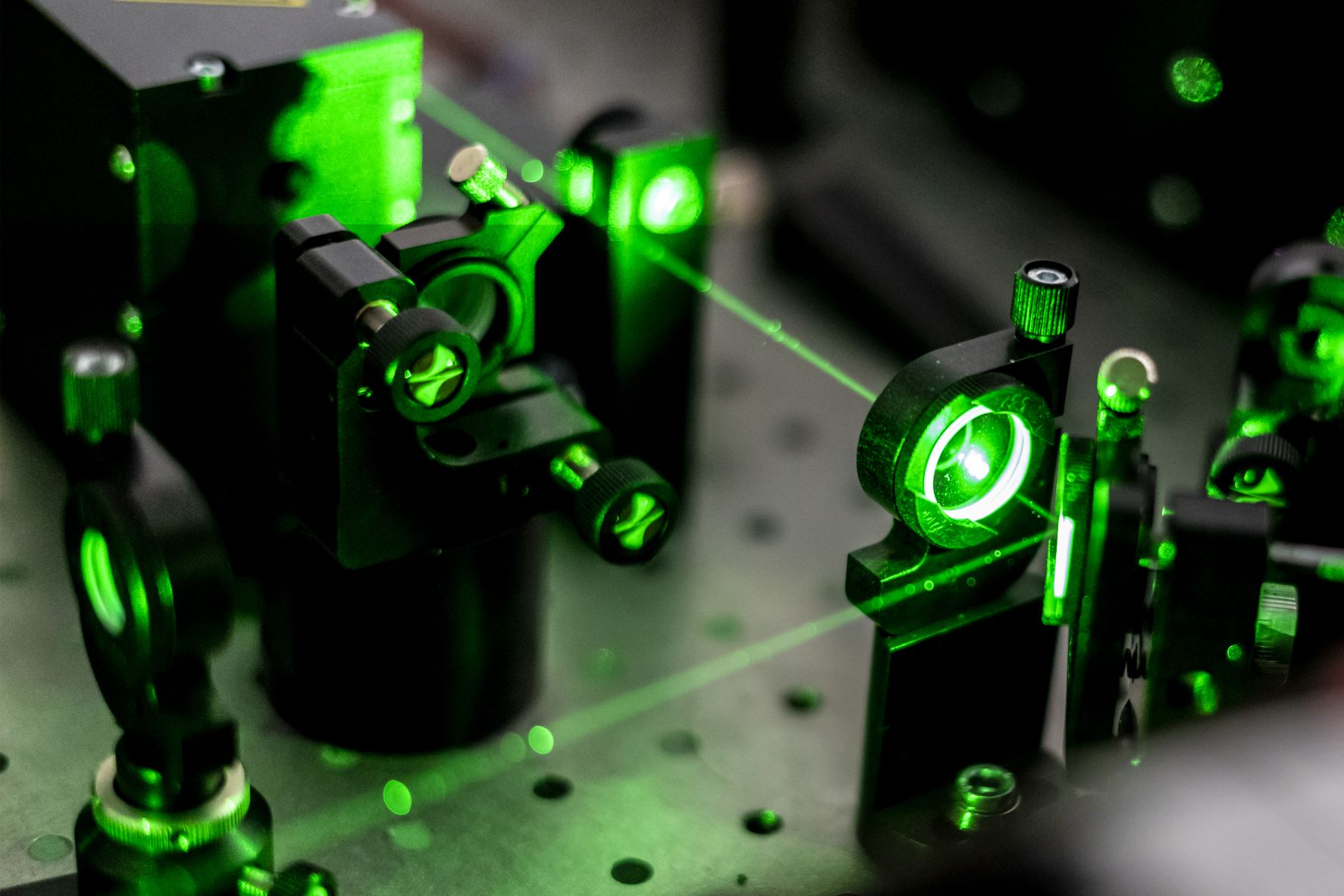

Lasers

Laser device manufacturers working with Palomar Technologies can:

- Achieve robust device quality with high accuracy placement and fine epoxy or solder and wire bonding control.

- Benefit from a complete solution for maximum performance of high-power laser assemblies with pick and place, vacuum reflow and wire bonding.

- Increase product performance, improve first pass yield and maximize the process while minimizing costly scrap.

Lasers are everywhere today and the market will continue to grow substantially. Materials processing consisting of fiber lasers, kW+ lasers and micro materials processing, along with communications are the largest sub-segments, followed by medical lasers and lasers in military applications.

High power semiconductor laser diode (HPLD) is an essential core component in a wide range of fields, specifically, modern laser material processing, laser remanufacturing, medical, and national defense-security fields. Key to any of these laser applications is the semiconductor packaging assembly using VCSELs or edge-emitting lasers (EEL) requiring high accuracy placement.

Packaging Assembly Challenges:

- High accuracy placement

- Alignment tolerances between components

- Difficult fiducials

- Very high accuracy X, Y, theta passive placement specifications

- High thermal conductivity required for bonds

Palomar Technologies knows how to solve the packaging challenges associated with lasers. The HPLD typically uses a eutectic AuSn process which the Palomar 3880 Die Bonder is perfectly suited. For a better signal-to-noise ratio, fine ribbon is used for the optical interconnects from the ICs to the optical components (VCSELs and photodiodes). The Palomar 8100 Wire Bonder provides accurate wire bonds, and the Palomar 9000 high-speed fine Wire Wedge and Ribbon Bonder is used for the fine ribbon. Lastly, the SST 8300 Vacuum Pressure Soldering System offers fluxless eutectic solder attach.