VisionPilot®

VisionPilot®

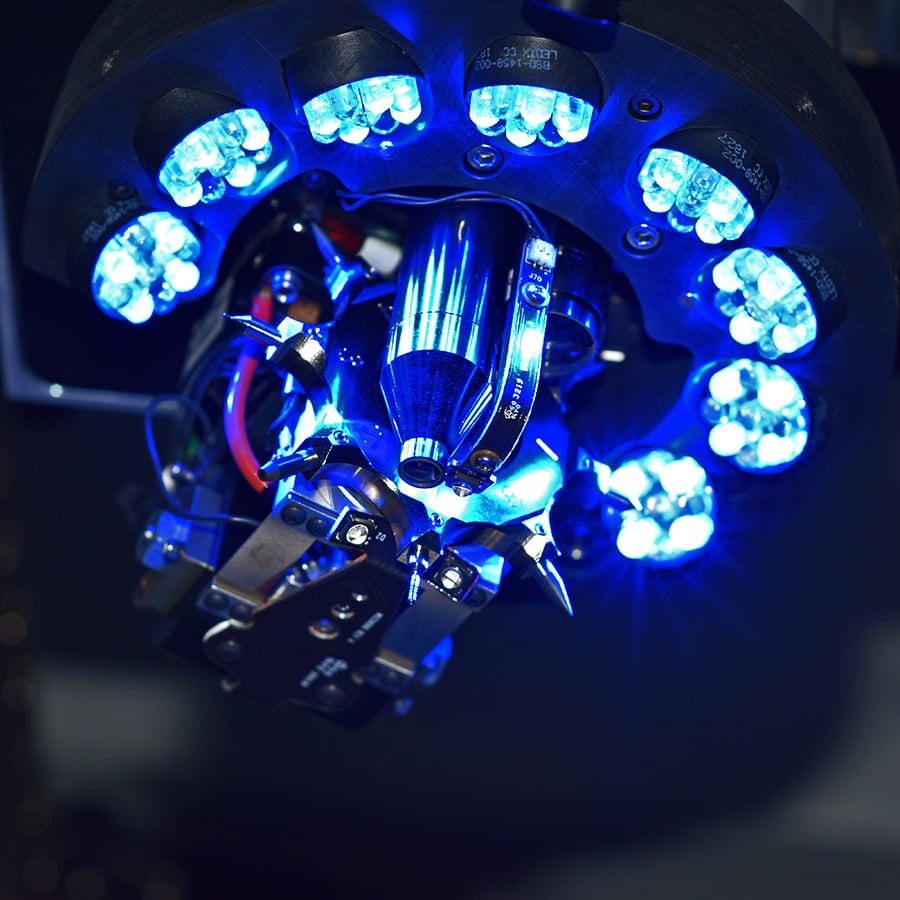

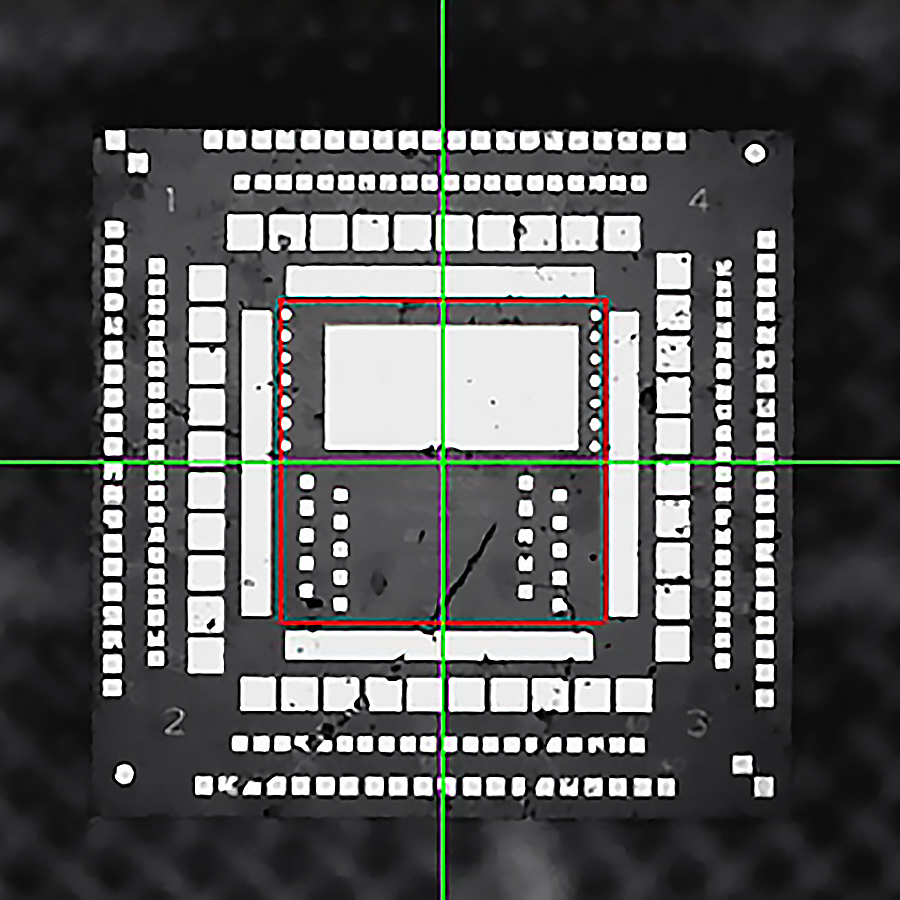

VisionPilot® is a state-of-the-art referencing technology that sets a new standard for vision processing on Palomar’s die and wire bond platforms that maximizes throughput and enables part inspection both before and after bonding. In contrast to standard referencing technology, VisionPilot utilizes advanced geometric pattern matching technology to reliably and accurately locate parts that are randomly oriented or have greyscale variations. It does so by using a set of boundary curves that are not tied to a traditional pixel-grid. It offers a wide range of tools and features to address the typical challenges of pattern recognition. This includes, but is not limited to, radar referencing, synthetic models, and active feedback.

- Large complex hybrids

- HB/HP LED arrays

- Optoelectronic packaging

- Microwave modules

- RF packages

- Hybrid microcircuits

- MEMS / MOEMS

- VCSEL, PD, DFB Laser, Lens Attach

- Solid state lasers

- RF GaN 5G power amplifiers

- RF power amplifier

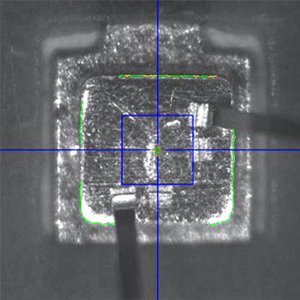

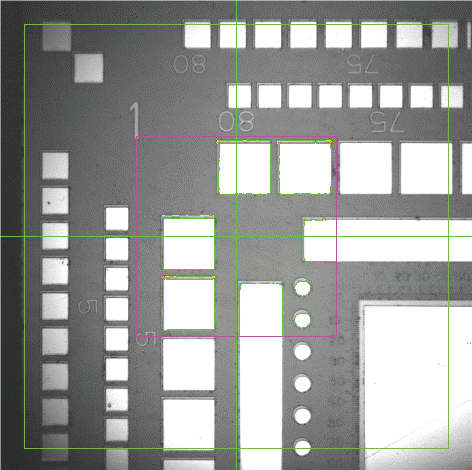

Radar Referencing®

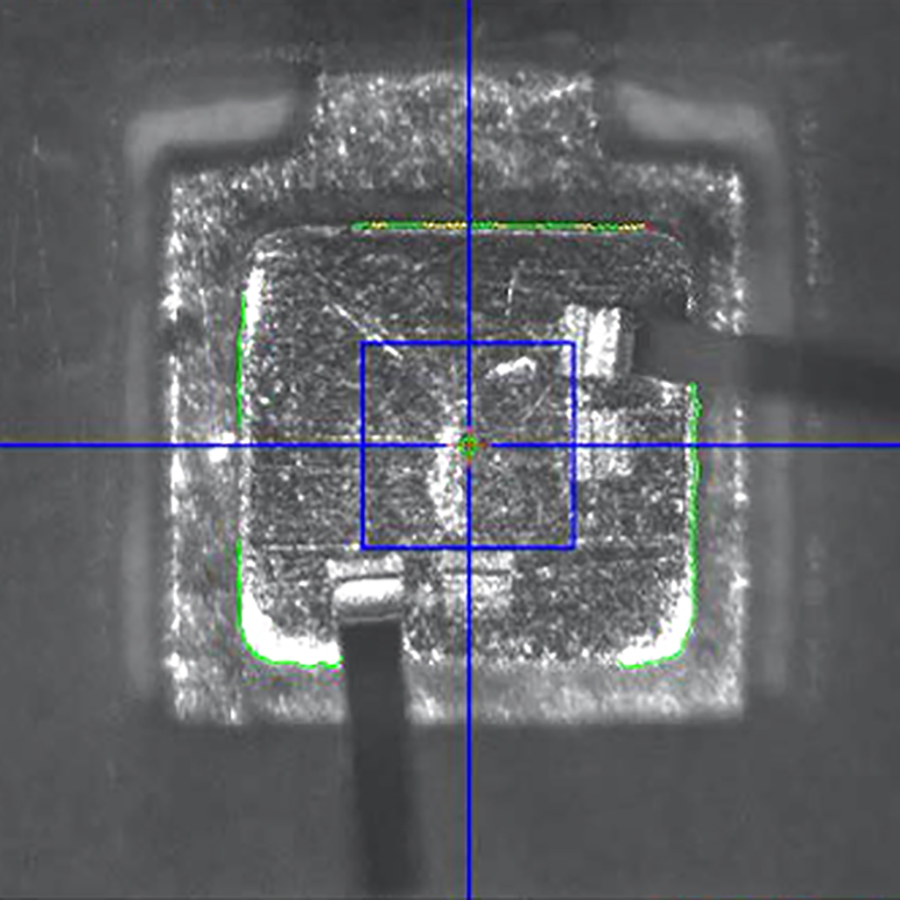

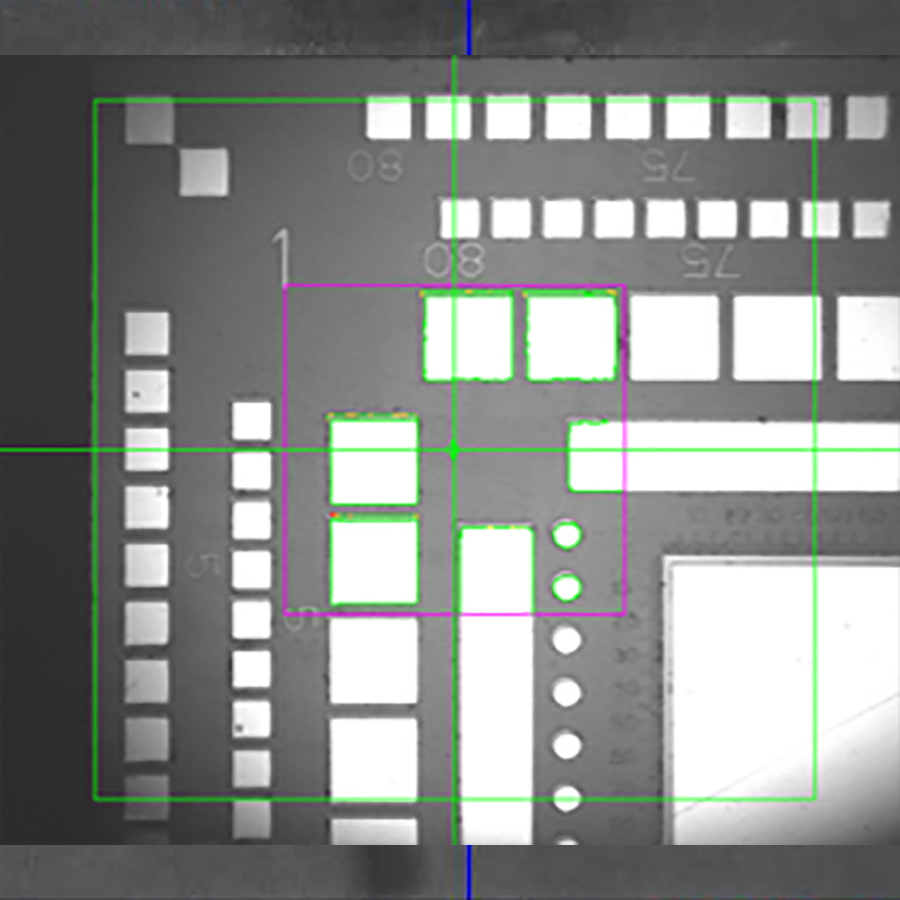

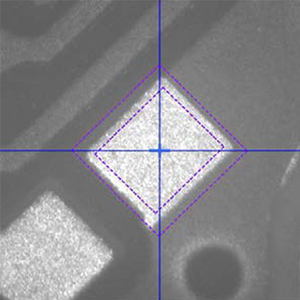

Radar Referencing® allows the bonder to use shapes instead of standard pixel-to-pixel comparison. It finds shapes by dividing contrasting shapes. Using this method, component variations such as scratches, contamination, and probe marks can be filtered out. By only looking at shapes and outlines, the bonder can locate the component accurately and repeatedly.

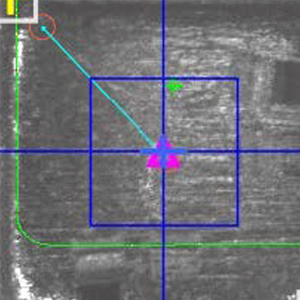

Synthetic Models

Synthetic models allow the user to teach perfect shapes as opposed to using a pristine component sample. Due to the manufacturing process of the some components, there will be surface variation; no two parts will look identical. By comparing the actual (imperfect) components to a perfect model, the bonder can accurately locate the component.

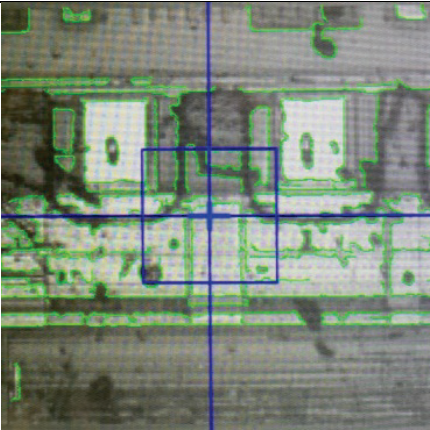

Active Feedback

Active feedback shows the user how accurately the bonder is identifying a component. It uses colors to quickly indicate strengths and weaknesses of that particular reference image. When the actual (imperfect) part is compared to the perfect synthetic model, green indicates that there is a good match, yellow is acceptable, and red is poor.

.png)