This is the last blog of our mini-series which discusses the frequently asked questions for the 3800 Die Bonder, 8000i Wire Bonder, and the 9000 Wedge Bonder. This week we are covering the 9000 Wedge Bonder. Check back next week for part two.

Why is the voice coil better than piezo?

The voice coil has a drive technology that can apply force and motion in two directions. Piezo technology applies force in one direction. The drive electronics are generally more complicated and their setup more difficult.

What is the shortest loop the system can generate?

Typical short loops, sometimes referred to as Lange Couplers, are as short as 5-10 mils. Looping control is difficult in these ranges, but can be accomplished (material and process dependent). A normal, controllable short loop is in the 10-15 mil range.

What is the longest loop the system can generate?

Loops up to 6mm and longer can be produced. Many factors play into making very long or short loops including: hardness of the wire (elongation), Delta Z bond heights, materials you are bonding and more.

Does missing wire detection mean machine detects lifting of the foot? Or, does it mean it detects a totally missing wire?

There are a couple areas of missing wire detection:

- Lost Wire Detection=Wire comes out of the de spooler and generates a signal.

- Process control=Monitors bond1 and bond2 deformation against upper and lower limits for each. If the wire is missing, then there will be very low deformation.

Would it be fair to say that clearance of the Palomar 45-60° clamp could allow you to use 45-60° for applications that would usually require a 90°, allowing the bonder to go faster?

Depending on the applications, we can advise which clamp would best for your specific project. You may need 90° depending on the loop requirements even if the 45-60° can clear.

How close can the Palomar 9000 get to the cavity?

We will need to see your package to help answer the question.

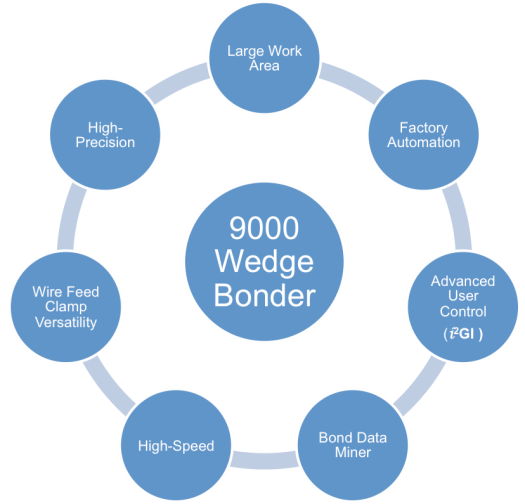

What are the 7 key differentiators to the 9000 Wedge Bonder?

- Large Work Area

- Factory Automation

- Advanced User Control (i2Gi)

- Bond Data Miner

- High-Speed

- Wire Feed Clamp Versatility

- High-Precision

What is the range of wedge tool lengths the 9000 can bond with?

Currently the 9000 uses a 0.750” tool. We are looking into expanding that to include a 1.078” tool in the future.

Can the system perform both round wire bonding and ribbon wire bonding?

Absolutely. Change the wire, change the tool, and you can go back and forth between the two wire types with either Au or Al wire.

| 9000 Data Sheet | Modern Wedge Bonding eBook | i2Gi Data Sheet |

|

|

|

If you have more questions about the 9000 Wedge Bonder, please contact your Sales Manager or Katie Finney at kfinney@bonders.com.

____

Bradley Benton

Regional Account Manager, Western Americas

Palomar Technologies, Inc.