If automated assembly equipment is central to your business operation, it is important to maximize your machine’s up-time. An important consideration is Spare Parts. Do you have some of the key spare parts at your facility to help maximize machine up-time? If the answer is: “no”, Palomar Technologies can recommend specific parts to keep on-hand.

Manufacturing-based industries that rely on capital equipment always run the risk of part and component obsolescence. Staying proactive by communicating with your equipment service team about part inventory and available upgrades—either covered by contracts or a-la-carte—will yield longer equipment life spans.

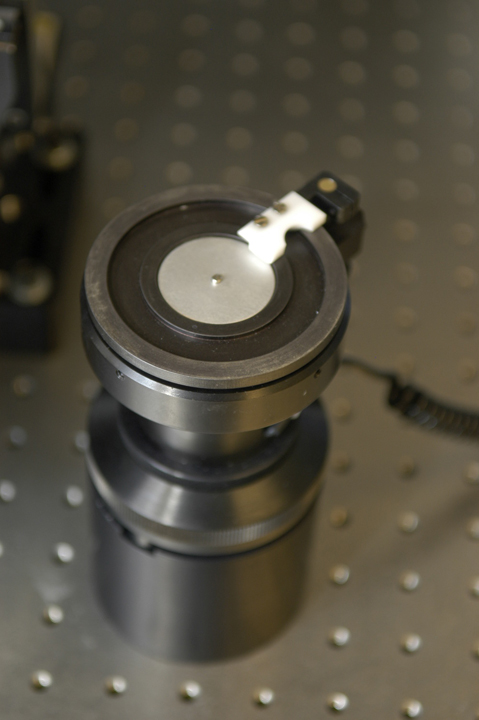

An important step towards maximizing machine up-time is analyzing your Bonder’s duty cycle. By knowing your Bonder’s usage, Palomar can identify the proper frequency for performing preventative maintenance. It is very important to perform preventative maintenance on your machines at the correct intervals. Such actions as: cleaning and lubrication, calibrations and diagnostic routines, inspections and replacement of common wear components will certainly preserve the up-time and productivity of your Palomar Bonder. Preventative maintenance is a critical task to properly maintain the bonder and ensure the bonder meets all factory specifications.

Do you have new machine operators and/or process engineers using the Bonders? Training your machine operators and process engineers on how to properly use and calibrate the equipment is very important to improve machine utilization and yields.

Enroll in our Bonder Boot Camp Courses to continue production at your Bonder’s maximum performance capabilities. Take advantage of offered hands-on training courses led by Palomar Technologies bonder experts, covering system operations, programming and proper maintenance. Bonder Boot Camp courses are designed for Palomar Technologies engineers to share decades of system, process and application development expertise in real- life laboratory environments.Standard and advanced training courses are available, both offering small class sizes for maximum hands-on experiences and one-on-one attention from instructors. Training can be held either at Palomar Technologies or at your site.

An example of the customized training one of Palomar Technologies’ customers received was a series of three Advanced Training Lessons. The first Advanced Training Lesson consisted of the set-up routine, assisting engineers to have a set-up/process run checklist to be verified daily (or every time they set-up or run a new/different device). This checklist allows the engineer to have a better understanding and proper set-up of their process.

An example of the customized training one of Palomar Technologies’ customers received was a series of three Advanced Training Lessons. The first Advanced Training Lesson consisted of the set-up routine, assisting engineers to have a set-up/process run checklist to be verified daily (or every time they set-up or run a new/different device). This checklist allows the engineer to have a better understanding and proper set-up of their process.

The second Advanced Training Lesson involved executing, trouble shooting, and modifying the existing program. This allowed further understanding of the engineer’s program and determined potential problems before they occur.

Finally, the third Advanced Training Lesson included creating and editing a new program which allowed the engineer to get a feel for how this process works, as well as a deeper understanding of the program from conception to completion.

Palomar provides high value training by understanding the goals of our customers and their areas of expertise. Maximize your machine’s up-time and let the machine and process experts at Palomar Technologies provide a customer training solution for you and your employees. By performing regular preventative maintenance and training your machine operators and process engineers how to properly use and calibrate the equipment, you can ensure that you are taking the correct steps toward maximizing your machine’s up-time.

Download these resources for more information:

| Boot Camp Data Sheet | Process Development Services |

|

|

----

Tim Hughes,

Director of Global Customer Service

Palomar Technologies, Inc.