Last week was the 15th anniversary of the Strategies in Light technical conference. Over 5,000 people attended the conference, and more than 200 companies exhibited – including Palomar Technologies. The number of both attendees and exhibitors increased over the 2013 conference totals. More than 95 speakers presented during the technical conference. An Investors Forum was also held on the first day, including 12 companies that interacted with VCs and corporate investors.

This conference focuses on solid-state lighting (SSL) which includes both light-emitting diodes (LEDs) and organic light emitting diode (OLEDs) technologies. The US Department of Energy claims that SSL “has the potential to reduce U.S. lighting energy usage by nearly one half and contribute significantly to our nation’s climate change solutions”.

Optimizing Solid-State Lighting

In order for SSLs to replace more conventional and energy-hungry incandescent and fluorescent lighting technologies, they must deliver a large amount of light (lumens) at about 25% or less power consumption and last a very long time. It’s all about lumens per watt and functioning for more than 30-50K hours. But even at reduced energy levels, these technologies generate a significant amount of heat. This heat must be managed or the device’s life span is greatly reduced. The die attach method is critical to this thermal management. Once the LEDs are attached they must be wire bonded using very high-reliability methods.

The traditional method of managing this heat is by employing passive or active heat sinks. The trick is to get the heat out of the LED and into the heat sink so it can spread and dissipate the device-damaging energy. The attachment method is the critical link in this thermal management. The less the thermal resistance or the greater the thermal transfer of the interface, the harder you can drive the device to generate high lumen output that will last a long time.

Multiple die attach methods are currently used—conductive epoxies, sintered materials, and solders. Eutectic materials offer the highest thermal conductivity, and epoxy the least–both with advantages. For ultimate thermal transfer, 80/20 AuSn (the coolest of hard solders) is used. While this transfers the highest amounts of heat per unit area, the liquid eutectic point is >280C (high temperature) and it is 80% gold (expensive). Epoxy cures at a relatively low temp (150C is typical) and is the least expensive, but also has the lowest conduction of heat per unit area.

Sintered materials, a fairly new product for this market, fall right in the middle. They are categorized as being more expensive, having medium processing temperatures, and medium-to-high thermal transfer characteristics.

Solutions

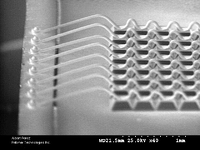

The 3800 Die Bonder provides fully automated solutions for all three methodologies. Once the bare die are attached, they must be interconnected and wired to the package. The wire bonds may need to carry a lot of current, and are usually between 1 and 1.5 mils in diameter and made of near pure gold (>99.99% Au). If the LEDs are positioned close together in arrays, they are usually wired in series. Matrix LED modules can generate a large amount of heat, but even larger amounts of light.

The 8000i Wire Bonder makes ultra high-reliability first level interconnects. The interconnect method is typically ball bonding; to improve interconnect reliability, stand-off-stitch or security bonds are included.

Low power consumption, high brightness, and long life are going to propel LEDs into every home and business over time. Outdoor and industrial lighting will all make the change to SSLs also. Palomar’s automated die attach and wire bond solutions offer many advantages to this industry.

The LED market outlook is bright!

Learn more about the growing market of LEDs by downloading these papers:

|

Automated Die Bonding Levels |

Check out these other resources for more:

|

8000i Wire Bonder |

|

|

Automated Eutectic

|

----

Bradley K. Benton

Western Regional Sales Manager

Palomar Technologies, Inc.