Wedge Bond Process Optimization Method for 1.5 mil Al Wire on Al Bond Pad

Download the Webinar!Modern wedge bonders have evolved since their early inception in 1957. This webinar will review the common challenges process engineers face when selecting a wedge bond machine configuration and developing robust processes. Wedge bond cases presented will show the tradeoff between process inputs and the resulting bond shapes, bond appearance of black ring, burrs, pull results, etc.

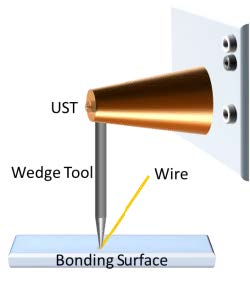

The purpose of this work was to optimize the process outputs: bond shape, black ring, burrs, and pulls on a die with aluminum bond pads. Process inputs included Force, Time, and Ultrasonic Level. An aluminum wafer was used to understand the basic relationship between process parameter inputs and outputs. The learning was then applied to a die with aluminum bond pads. Examples of non-compliance and compliance will be shown to help process engineers evaluate wedge bonds and make refinements.

The case studied was for an aluminum bond pad/Al wafer and 1.5 mil aluminum wire interaction that creates burrs around the bond (wire to pad interface), black ring on the bond periphery (wedge tool to wire interface) and the resulting pulls. Both the graphical and numerical results of the case study have clearly demonstrated the relationship between the typical process inputs and outputs, particularly bond shape, burrs, black ring and pulls. The findings in this study will provide a general guideline and a troubleshooting reference for wedge bonding process development.

Download to learn more...