功率模块: 常见的失效现象及解决方案

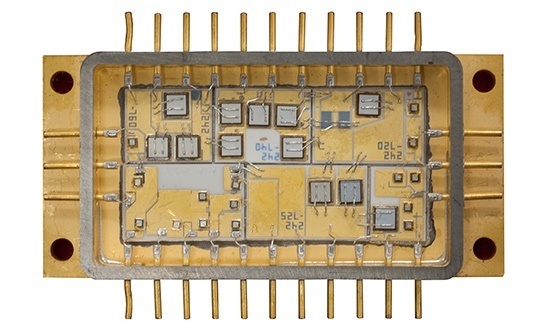

观看网络研讨会!Power Modules is a rapidly growing segment with high-growth applications ranging from electric vehicles, high-speed rail, and large medical devices. However, the stack of interconnects in power modules are the source of mechanical failures. Removal of heat between the DBC and baseplate is often the main source of thermal mismatches, making voids in this joint the most pressing challenge for power module manufacturers.

Palomar's Billy Wang and SST Vacuum Reflow Systems' Alex Voronel will take viewers through the challenges facing IGBT Power Module device manufacturers regarding typical failure modes. They will discuss how to solve them using a flux-less soldering process resulting in less than 1% voiding using a reliable Formic Acid or Forming Gas option.

功率模块是一个快速增长的市场,其应用范围包括电动汽车、高速铁路和大型医疗设备。然而,功率模块结构内的焊接处成为失效的根源,DBC和基板之间的热损耗也常常成为热不匹配的主要原因,控制焊接空洞率成为功率模块制造商最迫切的问题。来自Palomar中国区的Billy Wang(王文渊)和SST真空回流焊系统的Alex Voronel将和大家分享IGBT功率模块产品制造商在常见故障上面临的挑战。他们将讨论如何采用无助焊剂的工艺,借助可靠的甲酸或混合气体等选项,使焊接空隙率小于1%,从而解决这些问题。