Successful Void-Free Die Attach Using Vacuum Reflow Systems

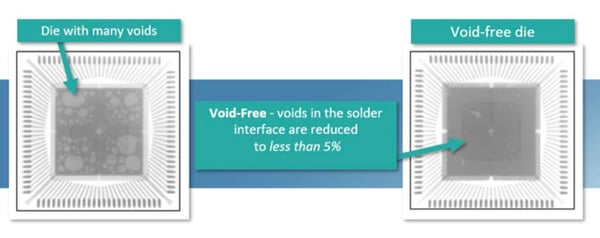

Download the Paper!There are many factors to consider when it comes to achieving desirable die attach; one of the most important of these factors is solder interface voiding. Voids in the solder interface contribute to various failure modes including overheating via non-uniform dissipation of heat and high mechanical stresses.

Vacuum reflow systems offer solutions to achieve low solder interface voiding through chamber pressure manipulations and surface treatment options. In addition, the correct solder material selection is key to achieving excellent bond quality. Each application is unique and requires careful consideration when it comes to solder material selection.

Selecting the proper material, solder, and process/tooling selection are essential to provide a successful void-free die attach using a vacuum reflow system.

Download to read more...