Multipurpose Wire Bonding –Bumps, Wires, Combination Interconnects, and Operation Efficiency

Download the Paper!Today’s multipurpose wire bonding machines are required to deliver a combination of wires, bumps, and specialty interconnects for RF, automotive, and optical markets with odd-form factor parts. These market production requirements are generally lower volume with a higher mix of products compared to typical high-volume semiconductor packaging of memory and logic. These markets also require multipurpose wire bonders to accommodate large work area, deep access, and a complex mix of bond surfaces, wire shapes, and bumps. The number of components in a package can vary from one with a few wires up to hundreds of components with

thousands of wires. Programming methods, process development, traceability, and rework are different for customers using this class of bonder.

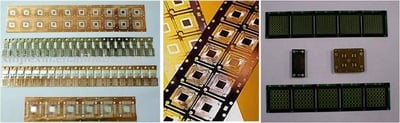

A survey of customer application cases shows the range of capabilities available to packaging engineers. The four primary cases presented highlight the range of applications that can be handled for odd-form factor packages and specific areas of focus to maximize productivity for these classes of products.

Case 1: Ball Bump Size and Shape Examples: acheiving119µm down to 44µm bonded ball diameters and range of shapes.

Case 2: Ambient Wire Bonding to a 6” Tall Package: demonstrating allowable bonding volume and tooling flexibility plus the ability to bond Au with substrates at ambient temperature.

Case 3: Batch Load Tray (Mechanical and Vacuum Clamping): allowing quick change over for radically different sized packages.

Case 4: Complex High Part Count Packages: supporting alternate parts and alternate bonding wires, standoff stitch, and security bonds require special features for programming and navigation methods to allow easy creation and navigation of complex programs for maximum productivity. Breakdown of timing and efficiency is provided showing programming efficiencies of 2X or better.

These cases will help packaging engineers extrapolate to their own cases and show how a multipurpose automatic wire bonder can be an effective way of automating or semi automating these manually or automatically presented packages for higher throughput, higher quality and consistency, and less labor usage for lower cost.

Download to read more...