Energy and Eco-Sustainability using Pressure-less Silver Sintering for RF Power Electronics

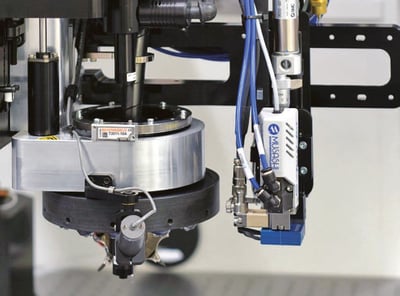

Download the Paper!A virtually void free die attach was successfully achieved using a fixed but critical volume of Ag sinter paste by a process of pressure-less sintering on a multi-axis cartesian style bonder, retrofitted with a high-speed jetting dispenser. While this process potentially offered an ideal combination of cost-effectiveness, control and speed, it required the development of additional software protocols to secure the level of performance demanded of the dispenser to meet exacting technical requirements. This proprietary adaption we term “Fixed BLT” software, and over five test pieces we were consistently able to deliver a fixed height bond-line of circa 70% of bond height, translating as 50μm before sinter and 30μm after. In each case the result was a virtually void free bond secured in a timely, repeatable, commercially effective manner. The absence of voids was verified through industry standard non-destructive analysis utilizing C-mode scanning acoustic microscope (CSAM).

Download to read more...