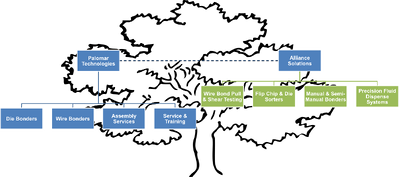

This week marks the Thanksgiving holiday, a time to celebrate autumn and give thanks with friends and family. Thanksgiving can also be a time to gather with extended family. Carrying on the theme of the season, we’d like to turn a spotlight on a few from our “extended family” of solution products—family tree included!

Palomar Technologies has supported thousands of organizations worldwide with automated high-precision die bonders and wire bonders along with experienced Assembly Services and agile Customer Services teams. Even further than equipment and production support, Palomar has also ramped up keystone solutions such as Process Development Services and the recent expansion of our demonstration, spare parts depot and training facility in the Asia-Pacific region.

We focus our engineering, support, development and inginuity in where we excel: fully automated, large work area and production hybrid die attach and wire bond equipment. We understand successful companies maintain a high-value rapport when they stick to what they’re good at, and we hold ourselves highly accountable to our equipment performance. However, we realize bonders may not be the only necessary systems for an entire production line. With our decades of expertise in application processes and equipment manufacturing, we have teamed up with complementary equipment vendors to help our customers obtain the complete suite of options for ample production performance. We like to think of them as our extended family.

Manual & Semi-Automated Bonders Hybond, Inc., designs and manufactures table top manual and semi-automated ball, wedge/wire bonders; epoxy/silver-glass/eutectic/laser diode die bonders; single point TAB bonders; DFS universal bonder test units and a variety of adjustable height heated work stages.

Hybond, Inc., designs and manufactures table top manual and semi-automated ball, wedge/wire bonders; epoxy/silver-glass/eutectic/laser diode die bonders; single point TAB bonders; DFS universal bonder test units and a variety of adjustable height heated work stages.

In a recent guest blog, Hybond's CTO/president offered a lens into accurate bond-line thickness for enhanced performance of critical die on the Hybond EDB-141 through a customer case study. The Hybond EDB-141 has become the primary die bonding machine for precision epoxy dispense and die bonding, replacing the cumbersome need for a two-machine system. Check out the complete blog: Accurate Bond-Line Thickness for Enhanced Performance of Critical Die; or download the Hybond data sheets to learn more.

Precision Fluid Dispensing Systems & Component Preparation GPD Global manufactures precision fluid dispensing systems for an array of production needs: low volume, high mix, R&D, and high volume 24x7 production. Their dispense systems can be configured for dedicated processes, or as a versatile system to handle multiple applications on a single platform.

GPD Global manufactures precision fluid dispensing systems for an array of production needs: low volume, high mix, R&D, and high volume 24x7 production. Their dispense systems can be configured for dedicated processes, or as a versatile system to handle multiple applications on a single platform.

While the GPD platforms—such as the Max and Max II series—have the precision and accuracy required in the microelectronics world, the dispense pumps are truly the “heart” of the system and allows the rest of the platform to deliver the production solution.

In a recent blog post, our Eastern Americas account manager shared a challenge to pick-and-place very small die. He discussed a customer requiring placing a 200µm square LED, in which the customer succeeded by using a fully automated die bonder for a “stamp transfer” method. This can provide 150µm dots; a very effective solution, especially for low-volume or prototyping. But what about medium-to-high volume? Using a capital-intensive, high-accuracy die bonder for stamping dots when you need it to be placing a high-volume of die may not be the most wise approach. This is where the GPD Micro-Dot Dispenser on a Max series platform did the job. Check out the blog for the complete story: Micro-Dot Epoxy Pump Dispenser - GPD Fluid Dispense Solution; or download the GPD Global data sheets to learn more.

|

|

Wire Bond Pull/Bond Shear/Die Testing Equipment & Die Sorting Systems Royce Instruments, Inc., supports an array of systems for a variety of process requirements, including wire bond pull testing, wire bond ball shear testing, die sorting and pick-and-place equipment. A Royce sales engineer wrote two fantastic guest blogs on their system capabilities: Universal Bond Tester for Hi-Rel Wire Bond & Die Attach Applications and Flip Chip & MEMS Assembly with High-Mix, Automatic Die Sorters.

Royce Instruments, Inc., supports an array of systems for a variety of process requirements, including wire bond pull testing, wire bond ball shear testing, die sorting and pick-and-place equipment. A Royce sales engineer wrote two fantastic guest blogs on their system capabilities: Universal Bond Tester for Hi-Rel Wire Bond & Die Attach Applications and Flip Chip & MEMS Assembly with High-Mix, Automatic Die Sorters.

Learn more by downloading the Wire Bond Pull and Ball Shear Testing eBook or the Royce Instruments data sheets.

|

|

We wish you a happy and healthy start of the holiday season!

----

Jessica Sylvester

Marketing Communications

Palomar Technologies, Inc.