Introduction to Automated & Semi-Automated Die Sorting

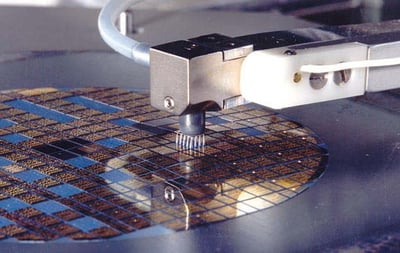

Download the eBook!Die sorting is used to separate the die of one wafer into categories of varying qualities or other characteristics. Even when all die on a wafer are intended to be identical, this is almost never the case. Sorting the die according to their characteristics becomes necessary in order to achieve a cost-effective, high-yield device packaging production.

MEMS and Direct Chip Attach LEDs are two examples of fragile die requiring flip chip prior to die attach. A required step before the flip chip bonding process is die sorting of these delicate die, which can include the option for die inversion.

While traditionally MEMS die were removed by hand through the use of a needle and vacuum wand or tweezers, today’s smaller, more fragile and complex devices require a more precise process.

As microelectronics device designs evolve, so must handling and assembly processes. A common example is with the process of removing product from tape after wafer processing and dicing is complete.

Download to read more...