Achieving High Accuracy Pattern Recognition For Die Bonding

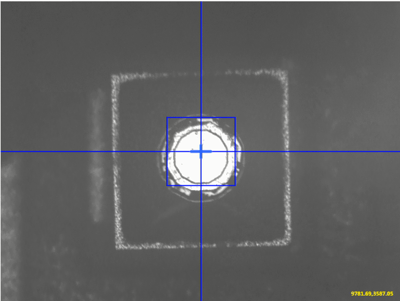

Download the Paper!When it comes to microelectronics and photonics packaging assembly, components such as die are placed onto packages. All automated die bonding systems require some type of vision processing for the machine to accurately locate the component before picking and placing the part. Because of this dependency on vision processing, the die must possess clear features to reliably assemble packages, especially when it comes to automated processes.

Standard pattern recognition technology, known as auto correlation, uses pixel-to-pixel comparisons. Using this method, it is ideal to use pristine components with clear features to teach patterns. Using the learned patterns, components with identical conditions must then be presented in order to build assemblies in an automated processes. Although this situation is ideal, it is not realistic because not all components will be identical.

Download the paper to read more...