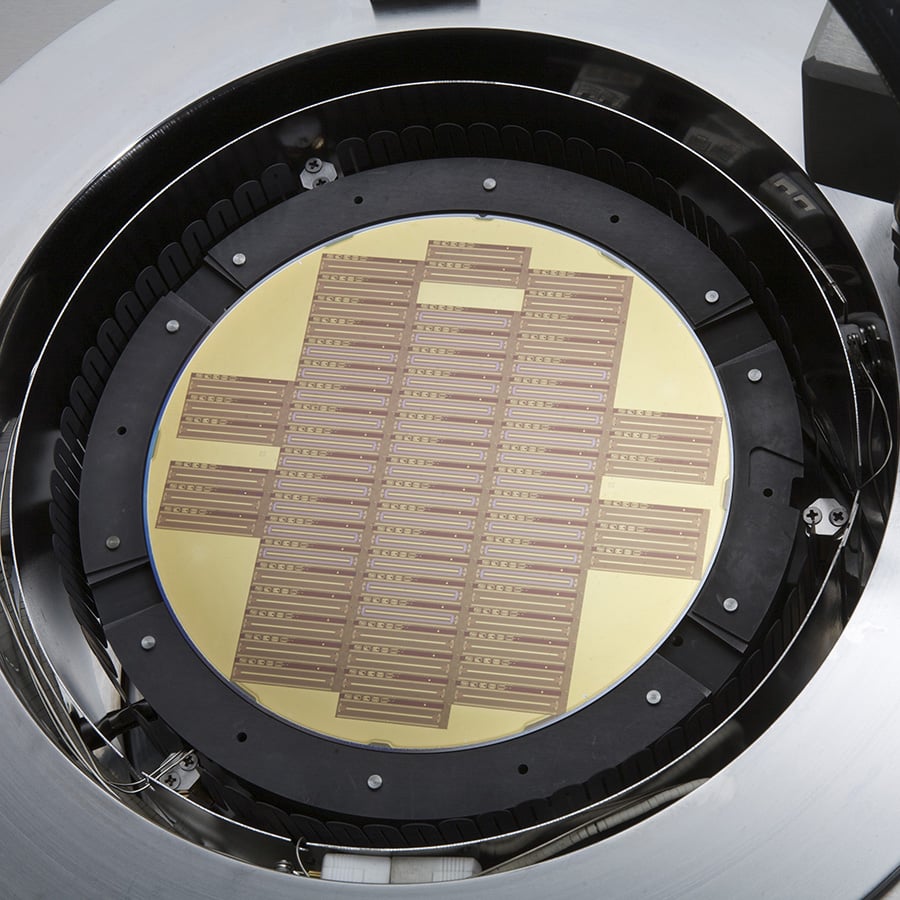

3250 High Vacuum Wafer Furnace

3250 High Vacuum Wafer Furnace

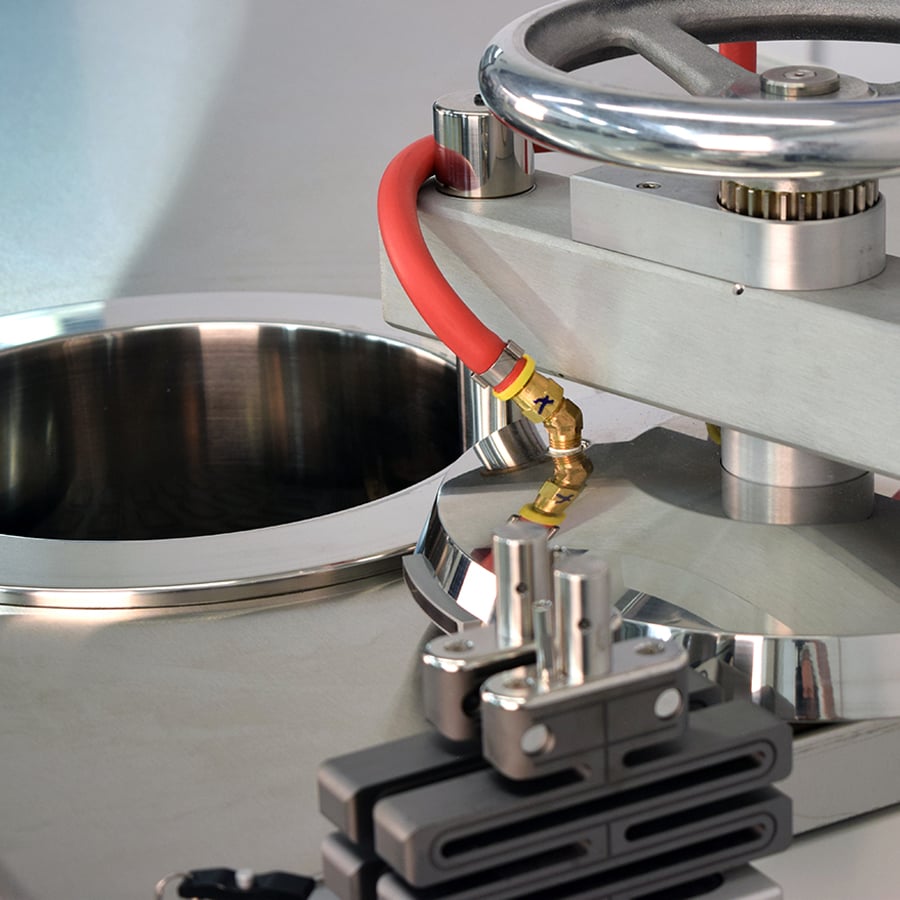

The SST 3250 is a high vacuum multi-atmosphere sealing furnace that has been designed for lid sealing on wafers of 150-200mm diameter. The system is fully operational at vacuum levels of 10E-07 Torr up to 12 psig with automatic selection and control of up to three process gasses. A closed-loop electronic pressure controller with integral capacitance manometer provides fine control of pressure and flow throughout the full operating range of the system.

- MEMS Package Sealing

- Void-Free Eutectic Die Attach

- Infrared Sensor Package Sealing

- Low Moisture Package Sealing

- Wafer Level Packaging

- Military Electronic Package Sealing

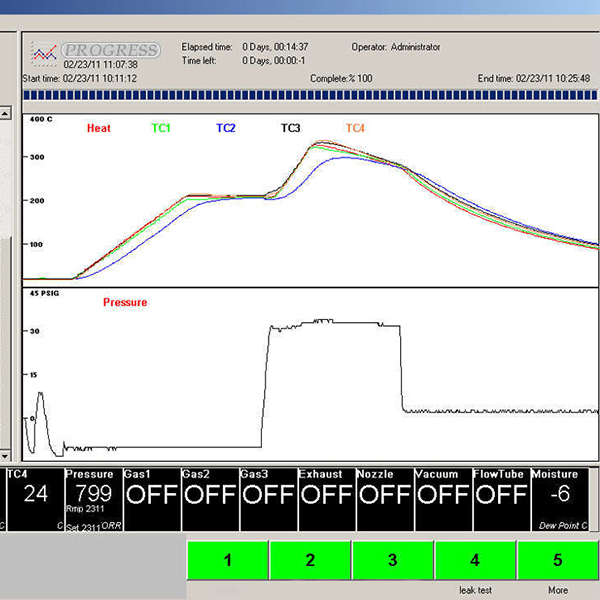

Run Analyzer

Run analyzer provides ability to graphically review data from logged profiles and export data. This includes real-time display of the thermal and pressure profiles as well as the ability to aid in process development by helping identify plating or material changes in your products.

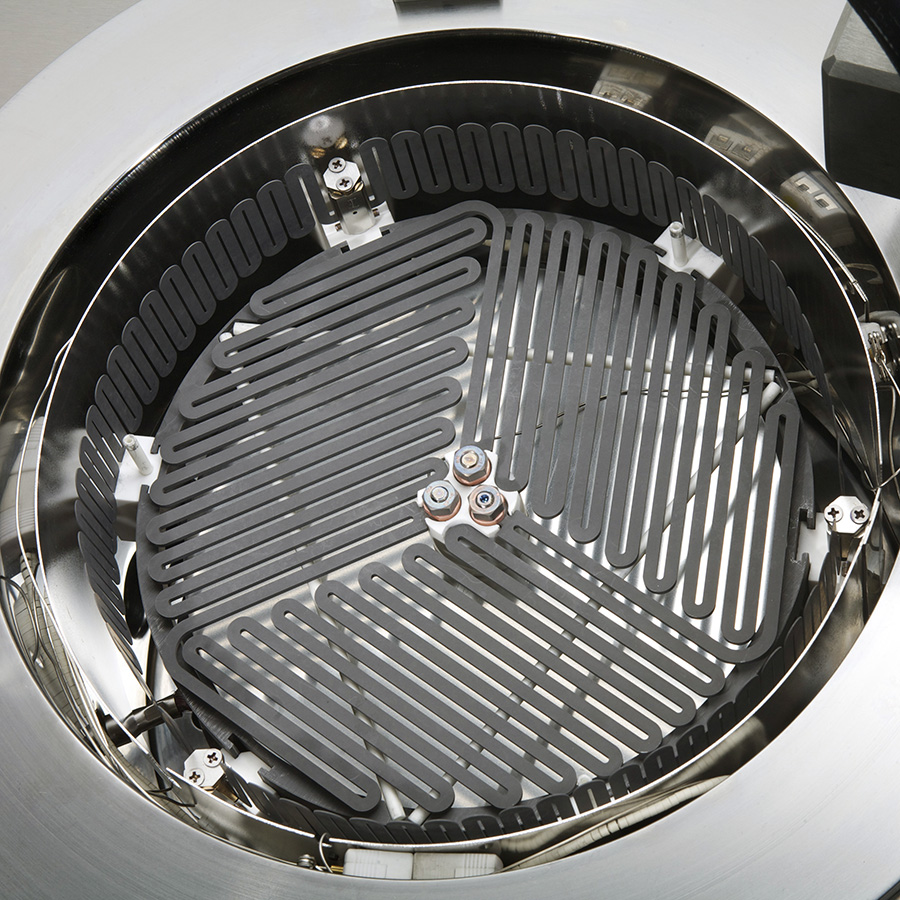

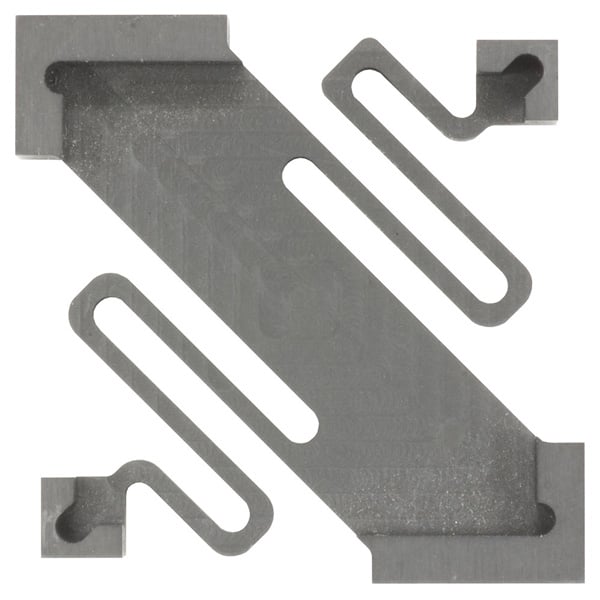

Graphite Tooling – Design and Manufacture

A full selection of products and services to meet your needs for precision graphite products. We combine our extensive inventory of premium graphite materials with engineering and design services, precision machining of graphite, ceramics and metals, and post-machining services such as cleaning, purification, coating and impregnation.