Soldering Gold Surfaces Using Gold-Tin Solder Material

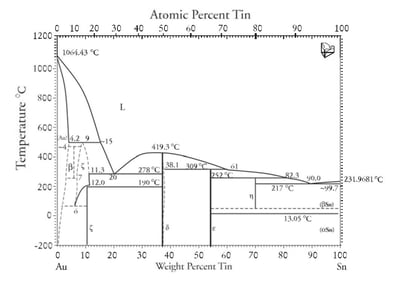

Download the Paper!The 80Au 20Sn solder alloy is primarily used in the microelectronics industry for lid seal and die attach applications and has a melting temperature of 278 °C. The surfaces to be soldered with this alloy must be metallized with gold or platinum material. Gold is the most commonly used metallization. For metallic parts, such as lids and metal packages, the gold is applied with a plating process. Solderable gold can be successfully vacuum deposited, sputtered or plated on ceramic, silicon and GaAs materials provided a compatible base coating, such as TiW, is applied beforehand.

Gold plated deposits for soldering applications must be of the highest quality. The gold must be free of porosity and contaminants that adversely affect solderability. The gold plating requirement for metallic details should be as follows: Underplate with solderable nickel sulfamate per QQ-N-290, 50-150 microinches thick, followed by gold plate per Mil-G-45204, Type III, Grade A, 50-100 microinches thick (Class 1).

Brighteners and other additives affect the degree of solderability. These should never be used for soldering applications.

Download to read more...