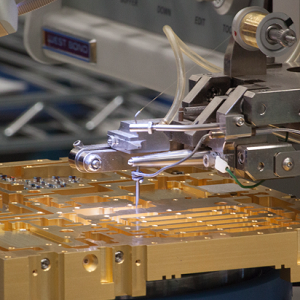

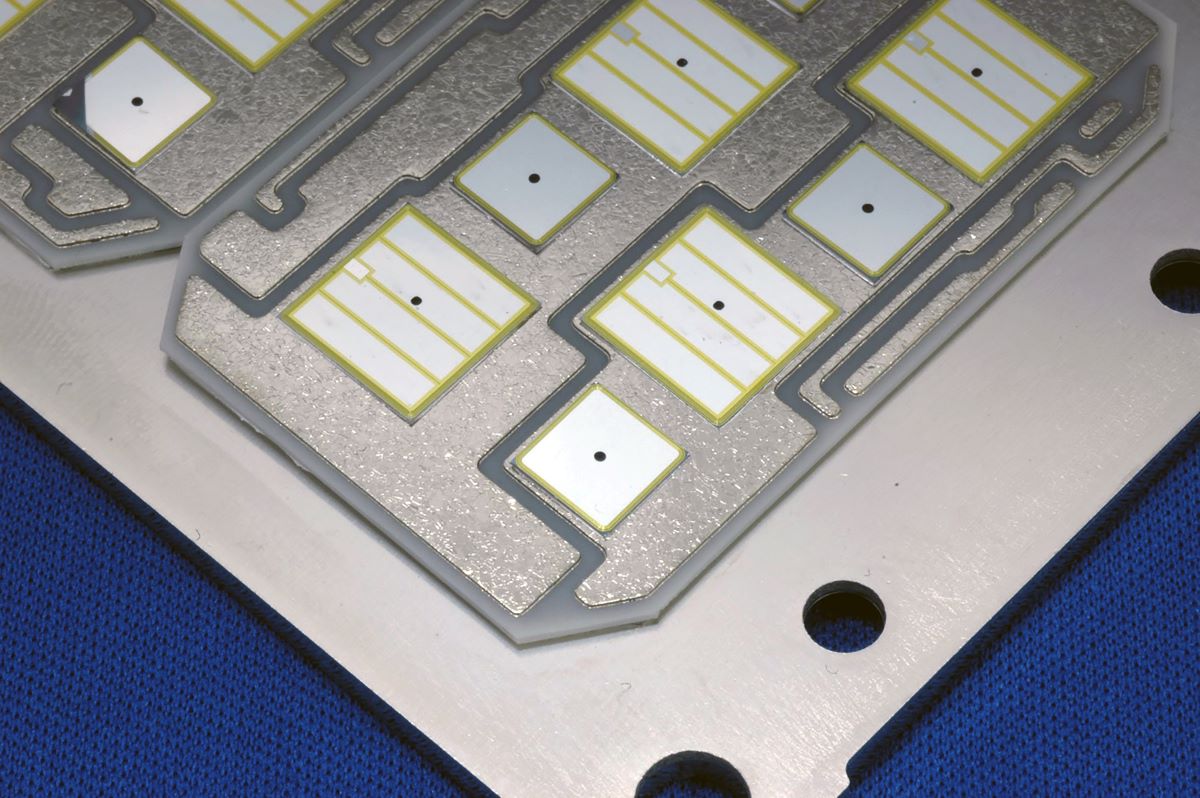

Palomar Technologies Presents Process Control & Traceability for Military and High-Reliability Semiconductors in Webinar

Webinar: June 23, 2021 at 8 am PST Carlsbad, CA – June 16, 2021 – Palomar Technologies, a global leader in delivering total process ...

Posted by Palomar Technologies MarCom Team on