Recently, Palomar Technologies acquired SST International as a partner in providing our customers with total solutions. There are many areas where our different capabilities complement each other. One area that both Palomar and SST concentrate on is void-free die attach.

Void-free Die and Substrate Soldering

Also known as eutectic die attach, void-free die and substrate soldering is key to the reliability of many advanced microelectronic products. This assembly process is used when heat must be transferred away from the die or other critical components to avoid thermal failure. The presence of voids increases the die operating temperature by inhibiting efficient heat transfer through the thermal interface material (TIM). Voids may be created by flux residue, surface oxides, trapped gas, and poor wetting.

SST's equipment and processes minimize voids through the precise control of vacuum levels, positive pressures, and thermal profiles. They offer a variety of systems, including the table top Model 1200 in which control of the processing atmosphere is integrated with the temperature controller through automatically actuated solenoid valves. An external vacuum pump is used to rapidly evacuate the chamber. Nitrogen gas (used for cooling and process) and one additional inert gas can be introduced into the chamber via ports in the lid and chamber bottom. Flow rates and pressures are set on the operator control panel.

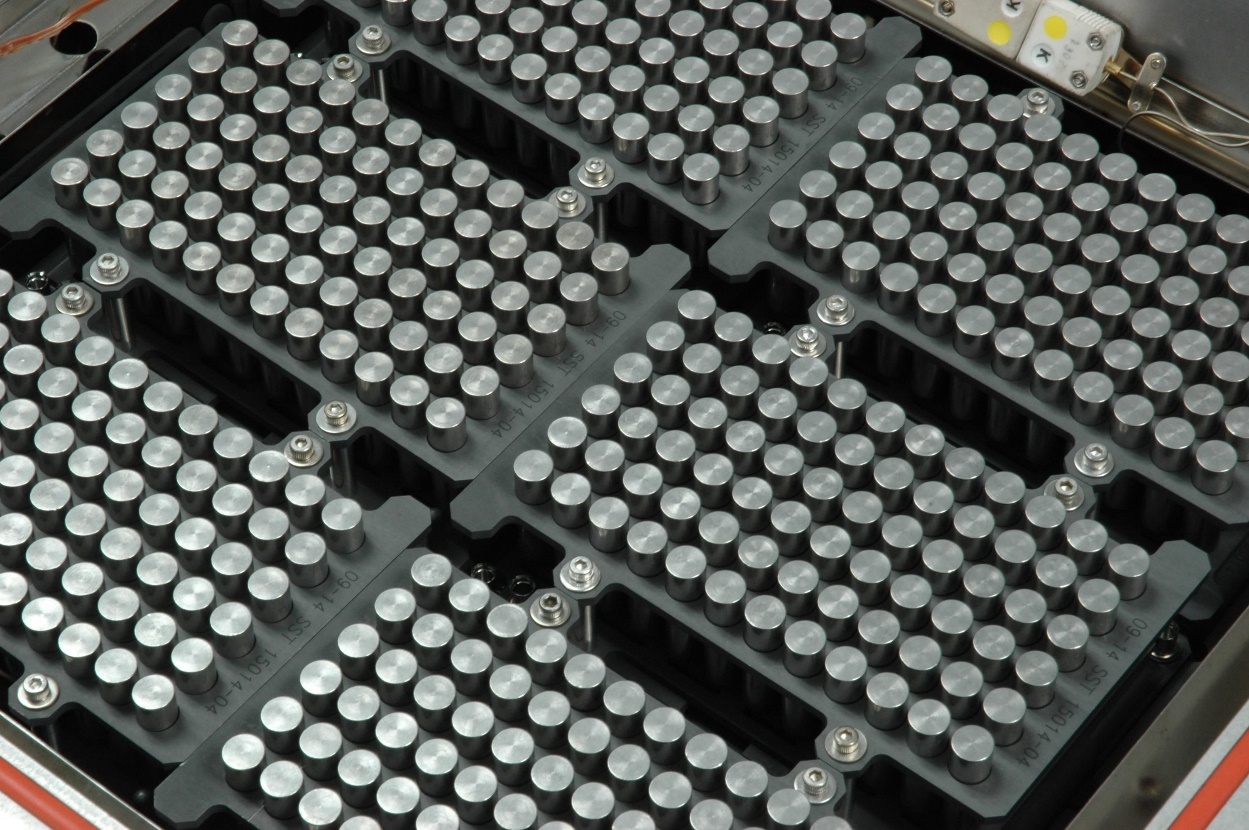

SST also has large batch load solutions, such as the Model 5100 which provides precise automatic control of heating and cooling ramp rates. This system allows for rapid heating up to 450ºC and rapid cooling in an inert gas environment from vacuum levels below 50 millitorr to pressures up to 40 psig. Machine control is provided by an embedded control system operating in a Microsoft Windows® environment. An unlimited number of process profiles can easily be created and stored in the controller. Process heating is provided over the entire work area by a close-coupled planar infrared heating element. SST uses ultra-precision graphite fixtures that have been designed and carefully manufactured to align the die to substrate, and weights to apply pressure during the reflow process.

Pulsed Heat System

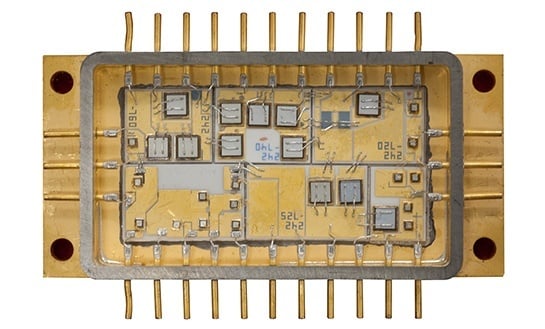

Palomar also provides void-free die attach in certain applications by providing an  “in-situ” solution using our Pulsed Heat System. The PHS system is integrated into the program and controls of our 3880 Die Bonder. The PHS enables precision eutectic die attach through a customizable computer-controlled heating and cooling profile. The hot-bar-based pulsed heat stage is capable of dynamic temperature ramping. The stage includes program-controlled clamps, an automated rotating shutter lid to create an enclosed gas chamber, cover gas control, and a programmable vacuum. Temperature control capabilities allow for custom temperature profiles with adjustable start times, ramp-up/cool-down rates and cooling gas flow.

“in-situ” solution using our Pulsed Heat System. The PHS system is integrated into the program and controls of our 3880 Die Bonder. The PHS enables precision eutectic die attach through a customizable computer-controlled heating and cooling profile. The hot-bar-based pulsed heat stage is capable of dynamic temperature ramping. The stage includes program-controlled clamps, an automated rotating shutter lid to create an enclosed gas chamber, cover gas control, and a programmable vacuum. Temperature control capabilities allow for custom temperature profiles with adjustable start times, ramp-up/cool-down rates and cooling gas flow.

Between Palomar and SST, we can meet your void-free eutectic soldering challenge. Download these resources for more information:

SST Model 1200 Data Sheet |

SST Model 5100 Data Sheet |

|

|

Pulsed Heat System eBook |

|

|

Void-Free Die Soldering Whitepaper |

----

Dale Perry

Regional Account Manager, Eastern Americas

Palomar Technologies, Inc.